- Overview

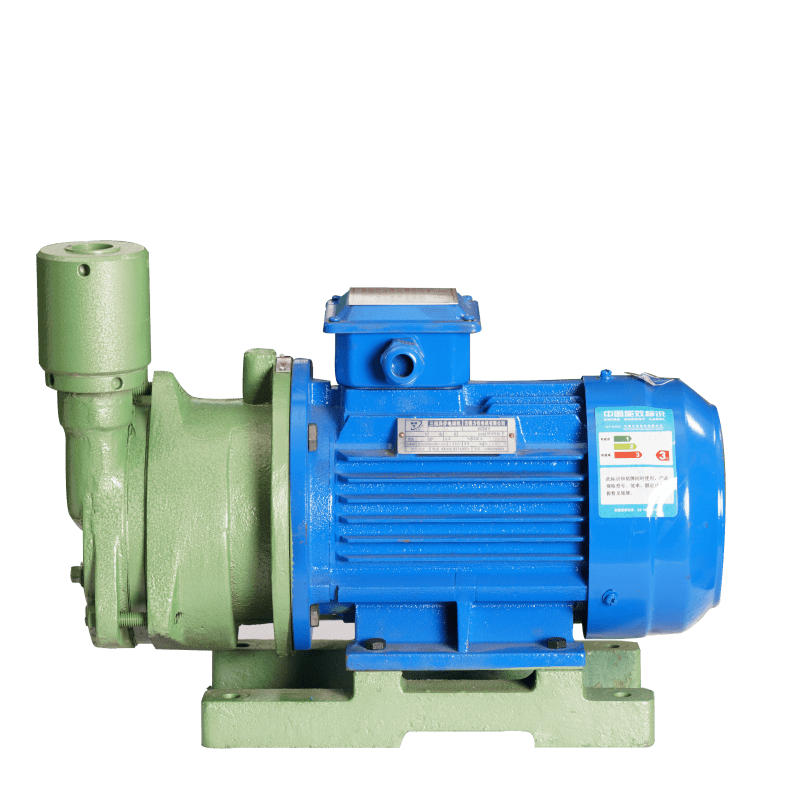

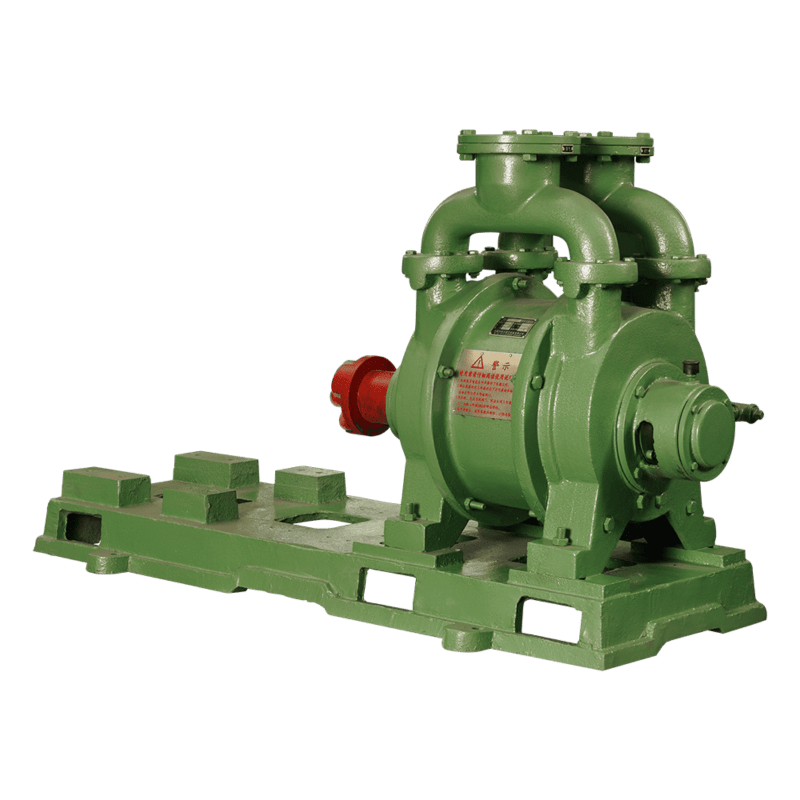

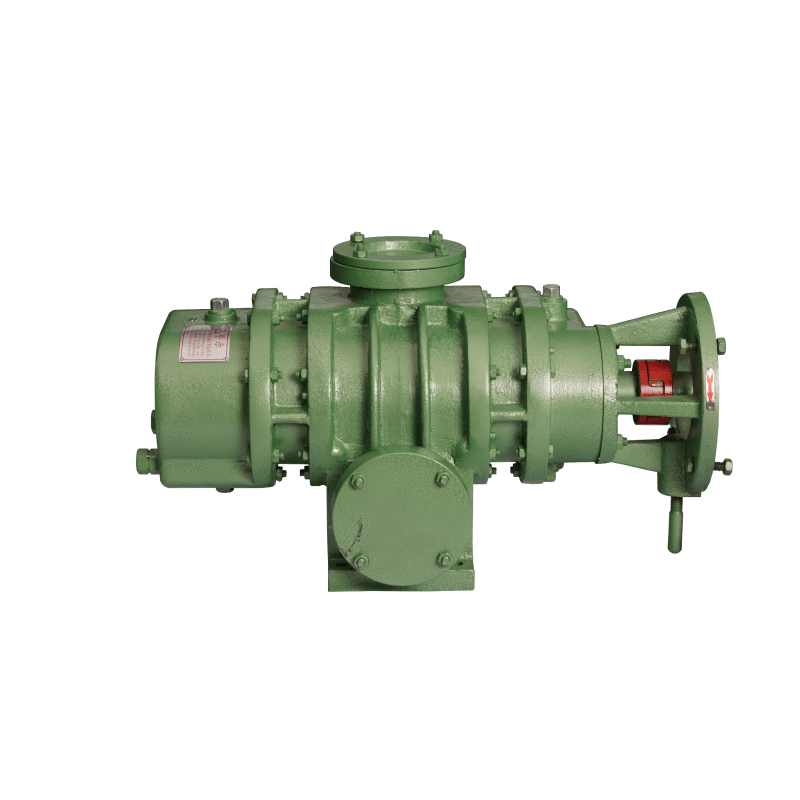

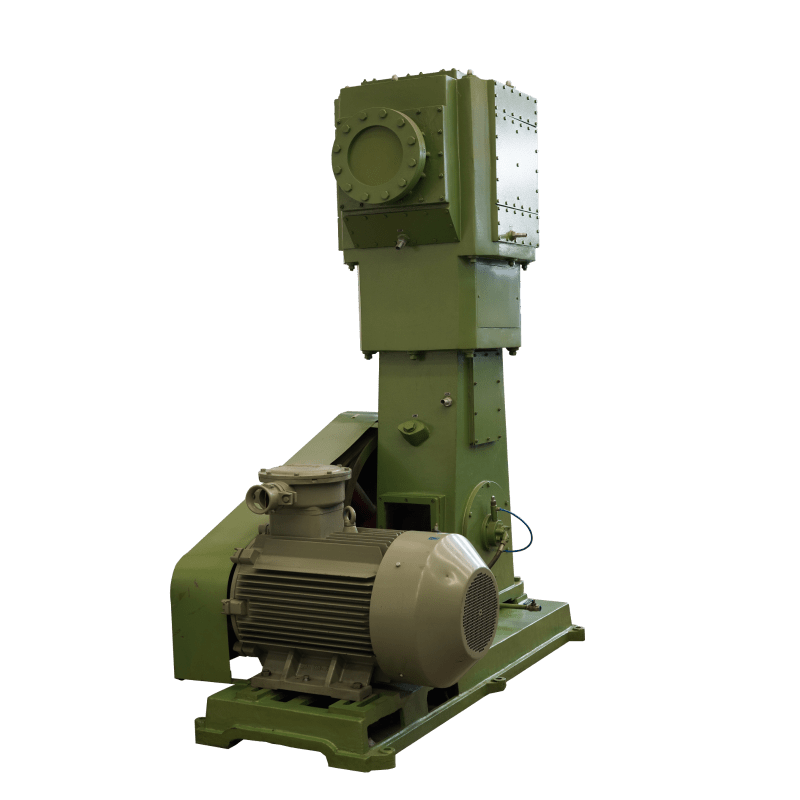

- Recommended Products

Product Overview

The Single-layer Stainless Steel Electrolyte Ton Drum, designed and manufactured byWuxi Sifang Youxin Co., Ltd. , is a high-performance industrial container specially engineered for storage and transportation of electrolytes, high-purity chemicals, and corrosive liquids.

Constructed from premium-grade SUS 304 or SUS 316L stainless steel, the drum provides exceptional corrosion resistance, ensuring product purity and stability even under harsh chemical or environmental conditions.

With a capacity of up to 1000 liters (1 ton), this single-layer structure offers robust mechanical strength, smooth internal surfaces, and reliable sealing performance, making it a preferred choice for industries such as new energy, chemical processing, lithium battery materials, and fine chemical applications.

The drum’s design complies with international safety and hygiene standards, combining durability, reusability, and environmental sustainability in one efficient solution.

Product Specifications

Product Name: Single-layer Stainless Steel Electrolyte Ton Drum

Nominal Capacity: 1000 liters (customizable: 800L – 1200L)

Material: SUS 304 / SUS 316L stainless steel

Wall Thickness: 1.2 mm – 2.0 mm

Internal Surface: Polished or electropolished (Ra ≤ 0.4 μm optional for high-purity use)

External Finish: Brushed, polished, or passivated surface treatment

Structure Type: Single-layer welded stainless steel tank body

Top Design: Closed or open top with manhole and safety vent

Bottom Design: Conical or flat base with liquid outlet valve

Welding Process: TIG automatic welding with full penetration and leak-proof seams

Sealing System: High-grade silicone, PTFE, or EPDM gasket for chemical compatibility

Operating Pressure: Atmospheric or slightly pressurized (≤ 0.3 MPa)

Working Temperature Range: -40°C to +200°C

Compliance Standards: ISO 9001, UN/DOT, GB/T 325.1, FDA & GMP (for electrolyte-grade and chemical applications)

Key Product Advantages

1.Superior Corrosion Resistance

The use of high-quality stainless steel ensures outstanding protection against acid, alkali, and electrolyte corrosion, preventing contamination or material degradation.

2.Excellent Product Purity

The seamless single-layer design and polished inner wall minimize residue accumulation, maintaining the chemical stability and purity of sensitive electrolytes.

3.High Mechanical Strength

The robust stainless steel structure withstands long-distance transport, stacking, and heavy-duty industrial handling without deformation or leakage.

4.Leak-proof and Safe

Precision TIG welding, combined with reinforced sealing components, guarantees full containment of hazardous or high-value materials.

5.Simple Cleaning and Maintenance

Smooth internal surfaces make the drum easy to clean, drain, and sterilize—ideal for repeated use in controlled environments.

6.Environmentally Sustainable

Fully recyclable stainless steel structure supports circular economy initiatives and reduces waste compared to disposable plastic IBC containers.

7.Customization Flexibility

Drum configuration (valves, ports, lifting rings, and outlet types) can be tailored to match specific electrolyte handling or chemical process needs.

Product Composition and Structure

The Single-layer Stainless Steel Electrolyte Ton Drum comprises several key parts:

1.Drum Body:

Constructed from rolled and TIG-welded stainless steel sheet.

Single-layer cylindrical structure designed for strength and corrosion resistance.

Internal polishing eliminates impurities and supports high-purity applications.

2.Top Section:

Equipped with a manhole cover, vent valve, or sampling port as required.

Optional safety pressure relief valve to ensure operator protection.

4.Bottom Section:

Conical or flat-bottom design for easy discharge of electrolytes.

Integrated stainless steel outlet valve (threaded or tri-clamp type).

5.Support Frame (Optional):

Reinforced stainless steel frame for forklift or pallet handling.

Can be fitted with anti-slip pads or shock-absorbing brackets.

6.Sealing Components:

Food- and chemical-grade gaskets compatible with acidic and alkaline electrolytes.

Airtight design prevents leakage and oxidation during transport or storage.

Assembly and Manufacturing Process

Material Inspection: Strict selection of certified SUS 304 / 316L plates with full traceability.

Rolling and Forming: Body sheet rolled and longitudinally welded using TIG technology.

Polishing and Surface Treatment: Inner wall polished or electropolished; outer wall brushed or passivated.

Component Integration: Assembly of valves, manhole, and sealing parts according to user specification.

Pressure and Leak Testing: 100% hydrostatic and air pressure tests ensure leak-free performance.

Final Inspection: Dimensional accuracy, welding integrity, and surface quality are verified before shipment.

Applications

The Single-layer Stainless Steel Electrolyte Ton Drum is widely used in industries requiring chemical purity, corrosion resistance, and structural durability, including:

New Energy Industry: Storage and transport of lithium battery electrolytes and conductive solutions.

Chemical Industry: For acids, alkalis, and high-purity chemical intermediates.

Pharmaceutical and Biotechnology: For sterile, non-contaminating liquid storage.

Food and Beverage: As a durable container for concentrated syrups, flavor bases, and additives.

Semiconductor and Precision Electronics: For ultra-pure liquid chemicals and etching solutions.

Quality Assurance

Each drum manufactured by Wuxi Sifang Youxin Co., Ltd. undergoes rigorous testing:

Hydrostatic Pressure Test: Verifies leak resistance and seam strength.

Corrosion Test: Confirms stainless steel stability in acidic or electrolyte environments.

Surface Roughness Test: Ensures compliance with hygiene and purity requirements.

Drop and Impact Test: Evaluates durability during transportation.

Final Inspection: Ensures each drum meets ISO and customer-specific quality criteria.

Frequently Asked Questions (FAQ)

Q1: Why choose a single-layer stainless steel design?

Single-layer drums are cost-effective while still offering excellent corrosion resistance and purity for electrolyte storage.

Q2: Can these drums be used for lithium battery electrolytes?

Yes. They are specifically designed to safely store and transport lithium-ion battery electrolyte materials.

Q3: What cleaning methods are recommended?

Rinse with deionized water or compatible solvents; steam sterilization is also supported.

Q4: Is customization available?

Yes. We can modify capacity, outlet type, and surface finish according to your process requirements.

Q5: Are these drums UN-certified for hazardous materials?

Yes, they can be manufactured to meet UN packaging certification standards for hazardous chemical transport.

Conclusion

The Single-layer Stainless Steel Electrolyte Ton Drum from Wuxi Sifang Youxin Co., Ltd. represents the perfect balance of purity, durability, and safety in industrial liquid containment.

Engineered for electrolyte and high-purity chemical applications, its corrosion-resistant stainless steel body and precision welding craftsmanship ensure long-term reliability and compliance with international standards.

Whether serving new energy materials, chemical processing, or precision manufacturing, this drum provides a clean, reusable, and environmentally sustainable packaging solution trusted by global clients.