- Overview

- Recommended Products

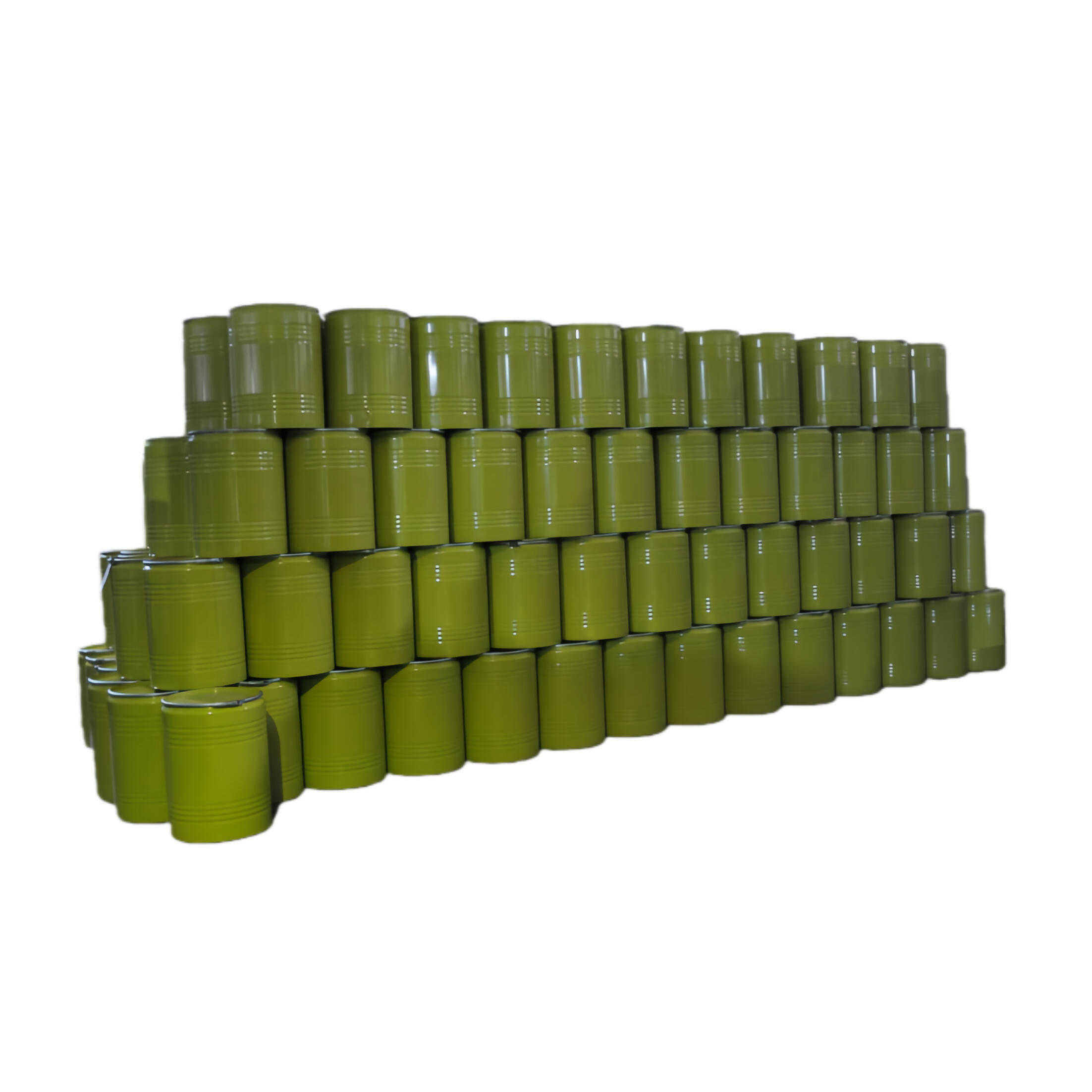

Product Overview

The Anti-static 1000L IBC, developed byWuxi Sifang Youxin Co., Ltd. , is a high-performance bulk packaging container specifically designed for the safe storage and transportation of flammable, volatile, or electrostatically sensitive liquids.

This IBC integrates advanced anti-static technology within its structure, using conductive polymer materials and grounded metal frames to effectively discharge static electricity generated during filling or movement. It provides the same structural strength and operational convenience as the standard 1000L IBC but with enhanced electrostatic protection and safety assurance, ensuring compliance with international safety standards for hazardous goods handling.

Product Specifications

Product Name: Anti-static 1000L Intermediate Bulk Container

Nominal Capacity: 1000 liters

Inner Container Material: Anti-static HDPE (surface resistance ≤10⁶ Ω)

Outer Frame Material: Galvanized or stainless steel cage with grounding connector

Pallet Base: Conductive steel or composite base, forklift-compatible on all sides

Filling Opening: DN150–DN225 anti-static screw or clamp lid

Outlet Valve: 2” or 3” conductive ball or butterfly valve

Working Temperature: -20°C to +70°C

Safety Grade: Suitable for use in static-sensitive environments (Zone 1 / Zone 2)

Certification: UN31HA1, ISO9001, ATEX, DOT

Key Product Advantages

1.Reliable Static Dissipation

The inner container is produced from anti-static HDPE blended with conductive carbon-based compounds, allowing static charges to safely discharge through the frame to ground during operation.

2.Enhanced Operational Safety

Prevents the buildup of static charges during filling, mixing, or transportation, significantly reducing the risk of spark-induced ignition in flammable environments.

3.Strong and Durable Construction

The reinforced metal cage structure and robust pallet base ensure mechanical strength, impact resistance, and stability under stacking or dynamic transport conditions.

4.Chemical Compatibility

Excellent resistance to acids, bases, solvents, alcohols, and hydrocarbon-based liquids, making it ideal for various industrial chemicals and flammable products.

5.Easy Integration and Handling

Compatible with automated filling, conveying, and discharge systems. The four-way pallet design supports forklifts and pallet jacks from any direction.

6.Reusable and Sustainable

Designed for repeated use, with easy cleaning and maintenance, contributing to cost reduction and environmental sustainability.

Product Composition and Structure

Inner Container:

Made of anti-static modified HDPE, ensuring electrical conductivity without compromising chemical or mechanical resistance.

Seamless blow-molded body with smooth internal surfaces for easy drainage and cleaning.

Outer Frame:

Galvanized or stainless steel cage, providing physical protection and integrated grounding points.

Reinforced crossbars enhance rigidity and prevent deformation.

Lid Assembly:

Anti-static cap with conductive sealing ring and optional venting device to prevent pressure buildup.

Bottom Discharge System:

Anti-static valve and outlet fitting for safe, controlled liquid discharge.

Sloped base ensures complete product evacuation.

Grounding and Conductivity:

Grounding connector at frame and valve ensures electrical continuity.

Resistance between components maintained within ≤10⁶ Ω for reliable static dissipation.

Manufacturing and Quality Control

Precision Blow Molding:

The anti-static HDPE is processed using advanced blow molding technology, ensuring uniform conductivity and high mechanical integrity.

Electrical Safety Testing:

Each IBC undergoes surface resistance and grounding continuity tests to verify anti-static performance.

Leakproof Testing:

Every unit is pressure-tested to ensure there are no leaks under operational conditions.

Stacking and Drop Testing:

The containers are tested for impact, vibration, and stacking loads to ensure compliance with UN transport regulations.

Inspection and Certification:

All products are inspected according to ISO and ATEX quality management systems, ensuring consistency and traceability.

Applications

The Anti-static 1000L IBC is suitable for applications where static buildup must be controlled to ensure safe operation.

Chemical Industry: Storage and transport of flammable solvents, alcohols, and resins.

Paints and Coatings: Handling of lacquer thinners, colorants, and varnishes.

Pharmaceuticals: Packaging of ethanol-based solutions or sanitizing agents.

Petrochemical Sector: Transfer of fuels, lubricants, and additives.

Battery and Electronics Industry: Handling electrolyte solutions and conductive liquids.

Quality and Safety Assurance

Each anti-static IBC is produced under strict quality control to guarantee safe, compliant, and long-term operation.

Electrical Performance: Surface resistance ≤10⁶ Ω verified per unit.

Mechanical Strength: Meets stacking and drop test standards.

Chemical Resistance: Compatible with a wide range of hazardous and non-hazardous liquids.

Traceability: Every container marked with a unique serial number and manufacturing batch code.

Certification: Fully compliant with UN, DOT, and ATEX requirements for static-sensitive materials.

Frequently Asked Questions (FAQ)

Q1: What is the main difference between anti-static and explosion-proof IBCs?

Anti-static IBCs prevent static charge buildup through conductive materials, while explosion-proof IBCs add enhanced metal shielding and grounding for higher hazard zones.

Q2: How often should the grounding system be checked?

It is recommended to inspect the grounding continuity before every filling and discharge operation.

Q3: Can the anti-static IBC be reused?

Yes. With proper cleaning and resistance checks, it can be reused multiple times safely.

Q4: What types of liquids are most suitable?

Ideal for flammable, volatile, or electrostatically sensitive materials such as alcohols, solvents, paints, and coatings.

Q5: Does it support automation systems?

Yes. Its dimensions and structure conform to ISO standards, making it compatible with standard automated filling and transport systems.

Conclusion

The Anti-static 1000L IBC combines safety, durability, and efficiency, providing an ideal solution for companies dealing with flammable or static-sensitive materials.

Its integrated conductive design ensures safe operations by preventing static charge accumulation during handling, while its robust construction and international certifications guarantee long-term reliability.

As a product ofWuxi Sifang Youxin Co., Ltd. , it represents a balance of safety engineering and industrial practicality, offering dependable protection and compliance for global chemical logistics.