- Overview

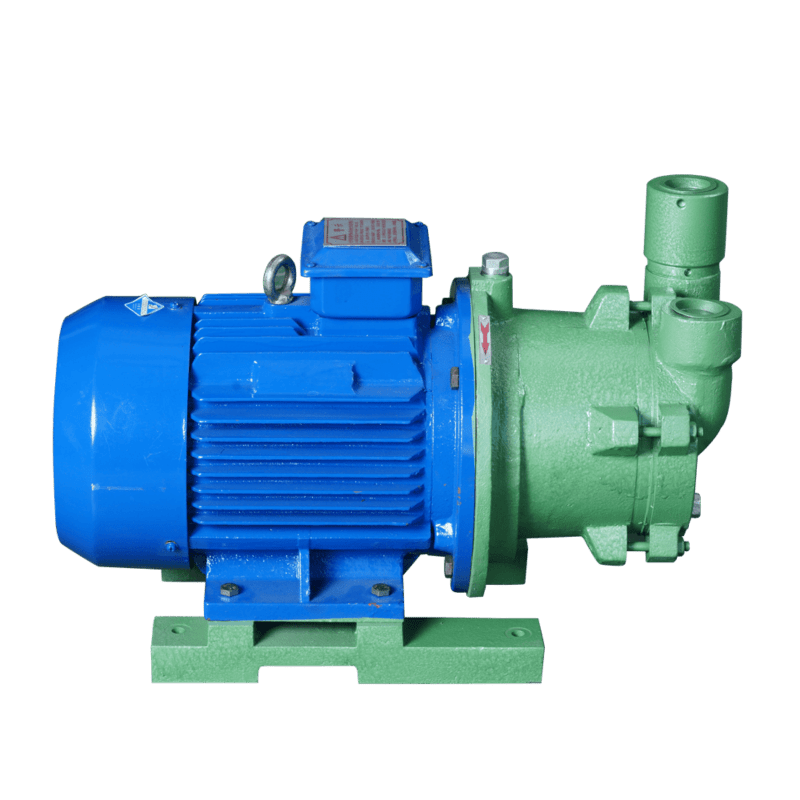

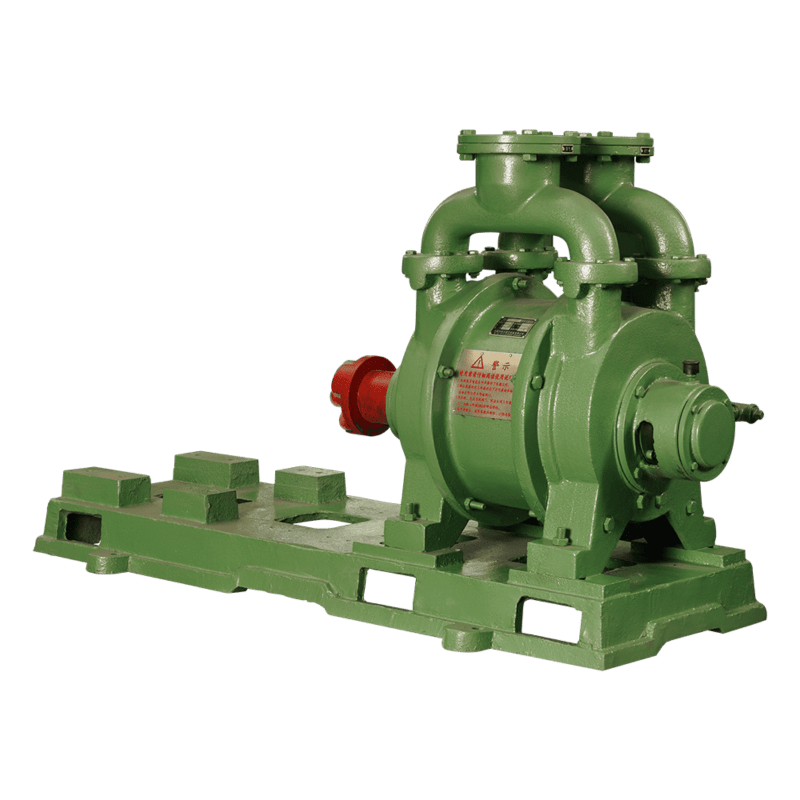

- Recommended Products

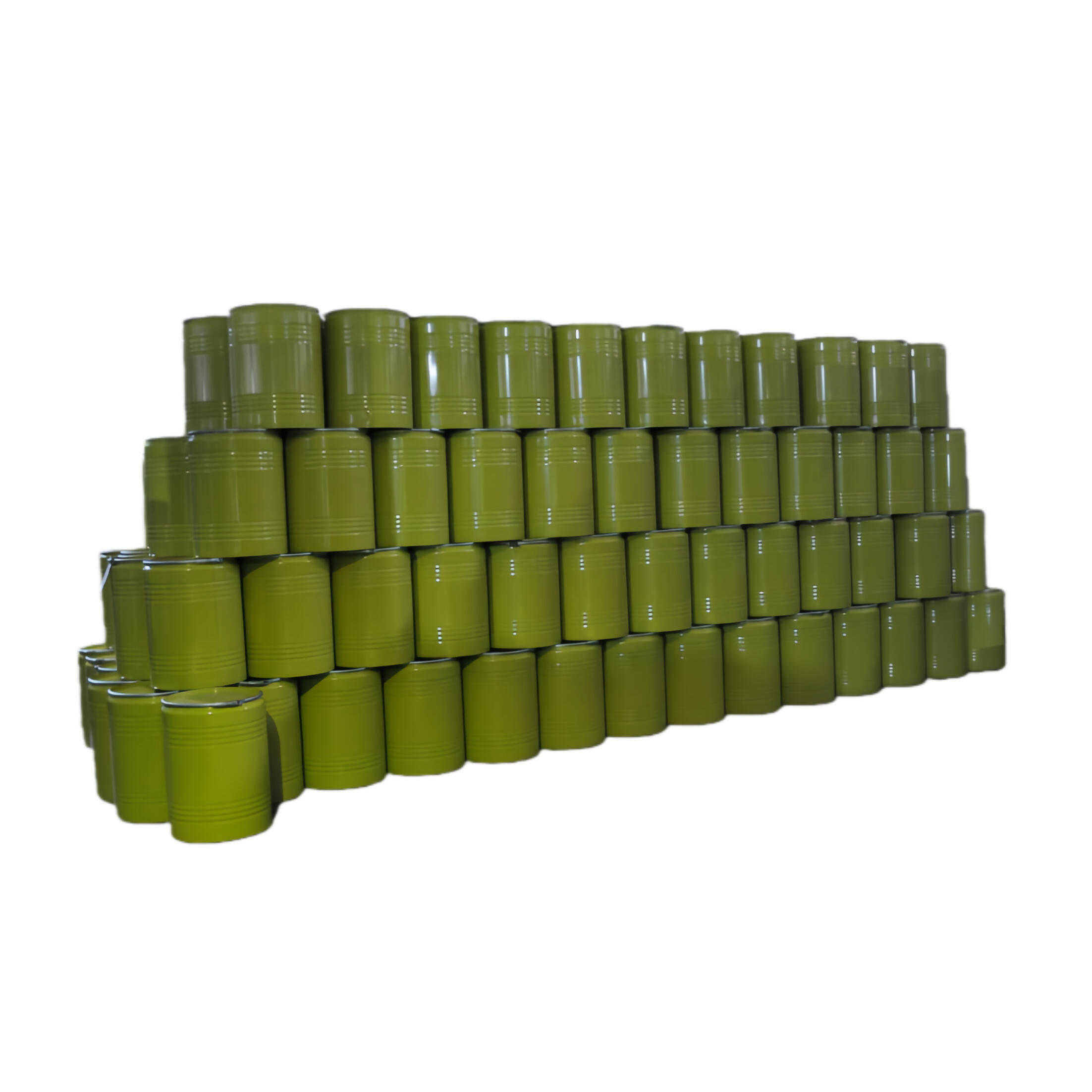

Product Overview

The Black Light-blocking 1000L IBC, developed byWuxi Sifang Youxin Co., Ltd. , is a specialized bulk container designed to provide optimal protection against UV light and visible light exposure. It is primarily used for the storage and transportation of light-sensitive chemicals, pharmaceuticals, food additives, and specialty coatings, where maintaining product stability and purity is critical.

The container’s black opaque inner tank effectively blocks ultraviolet and visible light, preventing photo-degradation, discoloration, or chemical reactions that could compromise product quality. Combining superior light-blocking performance, robust mechanical strength, and chemical compatibility, this IBC ensures safe, stable, and long-term storage of sensitive materials under varying environmental conditions.

Product Specifications

Product Name: Black Light-blocking 1000L Intermediate Bulk Container

Nominal Capacity: 1000 liters

Inner Container Material: Opaque black HDPE with UV stabilizers

Outer Frame Material: Galvanized or stainless steel protective cage

Base Structure: Reinforced steel or composite pallet, four-way forklift entry

Filling Opening: DN150–DN225 sealed lid with venting option

Outlet Valve: 2” or 3” high-precision ball or butterfly valve

Light Transmission Rate: ≤0.1% (400–700 nm visible range)

Temperature Resistance: -20°C to +70°C

Certification: UN31HA1, ISO9001, FDA food-grade (optional), REACH

Key Product Advantages

1.Superior Light-blocking Performance

The black opaque HDPE layer effectively prevents UV and visible light penetration, protecting contents from oxidation, degradation, or photochemical reactions.

2.Enhanced Chemical Stability

Ideal for light-sensitive or photo-reactive materials, ensuring purity and consistent quality during long-term storage or transportation.

3.Durable and Robust Design

Reinforced metal frame and impact-resistant HDPE body ensure safety during stacking, handling, and transport under harsh conditions.

4.Broad Chemical Compatibility

Suitable for acids, alkalis, solvents, and organic liquids while maintaining high corrosion resistance and structural integrity.

5.Clean and Hygienic Interior

Smooth inner wall design minimizes residue buildup, simplifies cleaning, and prevents cross-contamination between batches.

6.Environmental Protection

Manufactured with recyclable materials and designed for multiple reuse cycles, contributing to sustainability and reduced waste.

Product Composition and Structure

Inner Container:

Constructed from black, light-blocking HDPE blended with UV inhibitors.

Opaque material completely isolates internal contents from external light exposure.

Seamless molding prevents leakage and ensures consistent wall thickness.

Outer Frame:

Galvanized or stainless steel cage with multiple support ribs for rigidity.

Protects inner tank from mechanical impact during transport and stacking.

Top Section:

Sealed filling opening with optional pressure relief or venting cap, ensuring stable internal pressure during temperature changes.

Bottom Discharge Section:

Durable outlet valve and connector designed for precise, controlled discharge.

Sloped inner base guarantees complete emptying without residue.

Base Structure:

Integrated pallet base allowing 4-way forklift access for efficient handling.

High structural strength for multi-layer stacking.

Manufacturing and Quality Control

Light-blocking Material Formulation:

The inner container is manufactured using HDPE mixed with carbon black and UV stabilizers, ensuring consistent opacity and resistance to photodegradation.

Precision Blow Molding:

Ensures even wall thickness, stable structural strength, and leak-free seams.

Mechanical and Leak Testing:

Each IBC undergoes stacking, drop, and hydrostatic pressure tests per UN standards.

Light Transmission Test:

The container is tested under UV-visible spectrophotometry to confirm ≤0.1% light transmittance.

Quality and Traceability:

Each unit carries a unique serial code for traceable production and inspection records under ISO 9001 certification.

Applications

The Black Light-blocking 1000L IBC is ideal for products that are sensitive to light or require controlled storage environments to preserve their quality and chemical composition.

Pharmaceuticals: Storage of light-sensitive intermediates, reagents, and solvents.

Fine Chemicals: Handling of photo-reactive compounds and UV-curable resins.

Food Industry: Packaging of food-grade additives, flavorings, and colorants requiring protection from light-induced spoilage.

Coatings and Paints: Suitable for storing photosensitive coatings, inks, and catalysts.

Cosmetics Industry: Transport of essential oils and active ingredients susceptible to light degradation.

Quality and Safety Assurance

UV Protection Verification:

Every container is tested to ensure consistent light-blocking performance and material integrity.

Leakproof and Structural Testing:

Each IBC passes hydrostatic pressure and drop impact tests in compliance with UN31HA1.

Hygienic Standards:

Manufactured under clean conditions with optional FDA food-grade certification for sensitive contents.

Reusability and Maintenance:

Designed for multiple usage cycles with simple cleaning and reconditioning.

Sustainability:

Made from recyclable HDPE and steel components, reducing overall environmental impact.

Frequently Asked Questions (FAQ)

Q1: What is the main function of the black color?

The black material blocks UV and visible light, preventing photochemical degradation of light-sensitive contents.

Q2: Can it store food-grade materials?

Yes, a food-grade version compliant with FDA and REACH standards is available.

Q3: Is it suitable for outdoor use?

Yes. The UV-stabilized materials prevent sun damage and maintain performance even under prolonged outdoor exposure.

Q4: What types of liquids benefit most from this design?

Light-sensitive liquids such as flavorings, pharmaceutical intermediates, resins, and specialty chemicals.

Q5: Can it be reused?

Yes. The container is built for repeated use after proper cleaning and inspection, maintaining long-term cost efficiency.

Conclusion

The Black Light-blocking 1000L IBC combines light protection, chemical resistance, and mechanical strength to deliver a secure and reliable packaging solution for light-sensitive materials.

By integrating UV-blocking technology with the proven durability of Wuxi Sifang Youxin’s industrial design, this IBC ensures product integrity and stability from production to delivery.

It represents a high-performance and sustainable choice for industries that demand both safety and precision, offering unmatched reliability in protecting sensitive materials from the harmful effects of light exposure.