- Overview

- Recommended Products

Product Overview

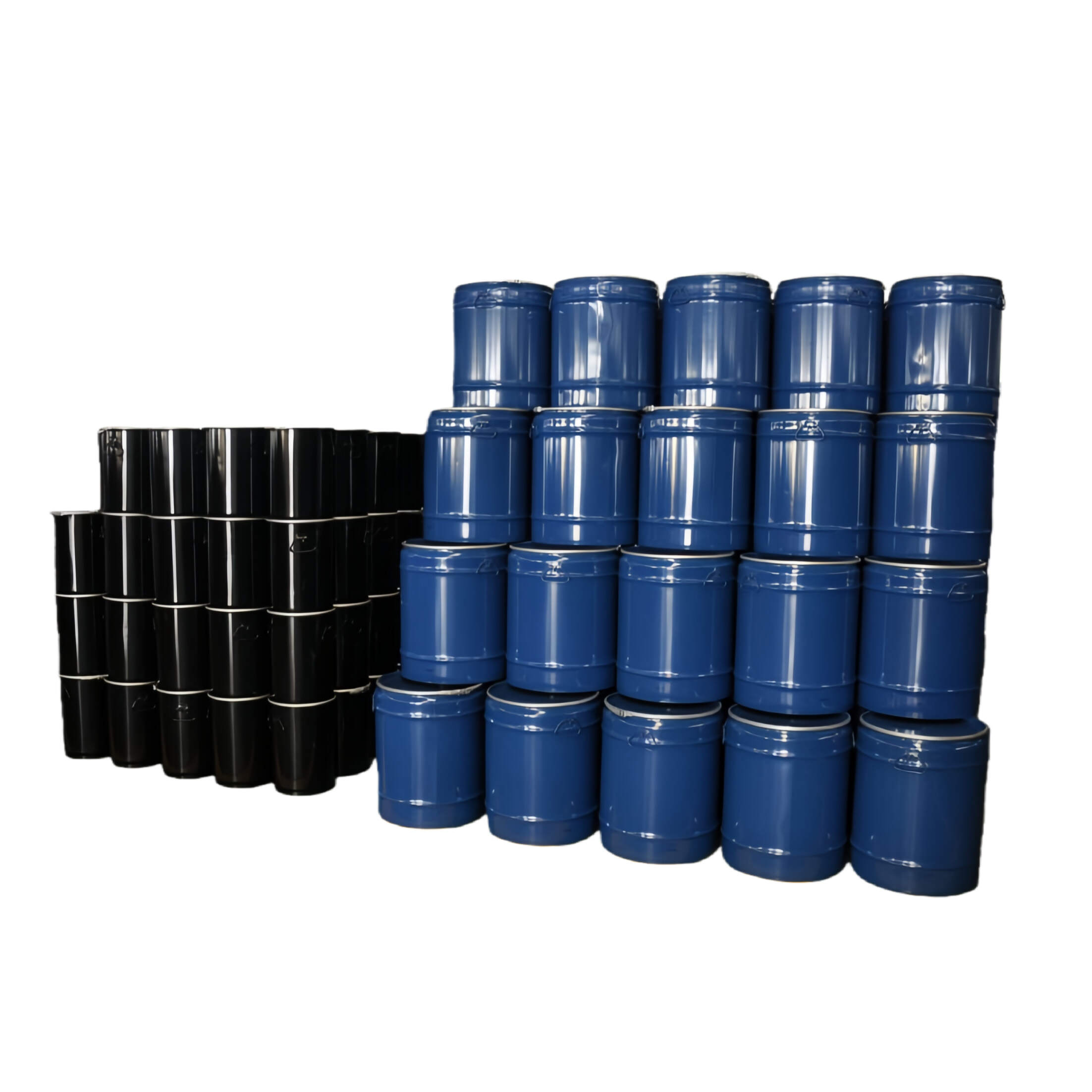

The Environmentally Friendly Phosphorus-Free Steel Drums developed by Wuxi Sifang Youxin Co., Ltd. represent the next generation of sustainable industrial packaging solutions. Designed with a strong focus on environmental protection and material performance, these drums eliminate traditional phosphate pre-treatment processes while maintaining excellent corrosion resistance, coating adhesion, and durability.

By adopting phosphorus-free surface treatment technology, Sifang effectively reduces heavy metal discharge and minimizes water pollution during production—meeting the latest global environmental protection standards (EU RoHS, REACH, and China’s Green Manufacturing Initiative). These drums provide safe, reliable containment for chemicals, coatings, lubricants, food ingredients, and other industrial products while ensuring environmental sustainability throughout the product life cycle.

Product Specifications

Type: Phosphorus-free eco-friendly steel drums (open-head or closed-head options available)

Capacity Range: 50L – 230L (common sizes: 200L, 205L, 210L, 230L)

Material: High-grade cold-rolled or hot-rolled carbon steel

Wall Thickness: 0.6 mm – 1.2 mm (customizable based on load and application)

Surface Treatment

Exterior -Water-based coating or low-VOC amino enamel

Interior -Epoxy-phenolic, pure phenolic, or PVF (fluoropolymer) lining

Pretreatment: Phosphorus-free surface activation technology ensuring paint adhesion and rust protection

Welding Process: High-frequency seam welding with anti-corrosion sealing

Colors: Customizable color, logo, and marking options

Standards Compliance: ISO, UN, and environmental management certifications

Key Product Advantages

1.Phosphorus-Free & Eco-Conscious Manufacturing

Traditional phosphate-based steel pretreatment generates wastewater containing phosphorus and heavy metals. The phosphorus-free technology developed by Sifang replaces this with non-toxic, biodegradable activation agents, dramatically reducing environmental impact while achieving the same or better coating performance.

2.Excellent Corrosion Resistance

The advanced surface treatment combined with Sifang’s optimized baking and curing process ensures long-term rust protection even in high-humidity or marine environments. The coating tightly bonds to the steel surface, enhancing product longevity.

3.Superior Paint Adhesion and Finish

The phosphorus-free conversion layer improves coating adhesion, prevents peeling or blistering, and provides a smooth and glossy finish suitable for both industrial and branded applications.

4.Energy Efficient & Low-Emission Production

The manufacturing process reduces energy consumption by eliminating multiple rinsing and heating steps, while water-based coatings minimize VOC emissions—making the entire production line cleaner and safer.

5.High Strength and Structural Stability

Built with precision-rolled steel sheets and robust welds, these drums maintain structural integrity during handling, stacking, and long-distance transport. Reinforced rolling ribs prevent deformation and enhance pressure resistance.

6.Customizable Design Options

Available in both open-head and closed-head configurations, with variable lining materials, thickness options, and color schemes, to meet diverse industry requirements—from hazardous materials to food-grade packaging.

Product Composition and Structure

1.Each Environmentally Friendly Phosphorus-Free Steel Drum consists of

Drum Body: Straight-wall or slightly constricted cylindrical shell, formed from precision cold-rolled steel.

Top & Bottom Ends: Welded with precision seams for airtight and watertight sealing.

Surface Layer: Phosphorus-free treated surface to enhance coating adhesion and corrosion resistance.

Coatings

Outer Layer: Water-based or amino baking finish for durability and weather protection.

Inner Layer: Chemical-resistant epoxy or PVF lining for safe contact with a wide range of materials.

Sealing System: Gaskets, clamps, or threaded bungs depending on drum type (open or closed).

2.Manufacturing Process Overview

Surface Cleaning & Activation: Using phosphorus-free, eco-safe chemical agents.

Rolling & Welding: Steel sheets formed and welded into cylindrical bodies.

Coating Application: Interior and exterior coatings applied via automated spray systems.

High-Temperature Baking: Ensures adhesion and coating hardness.

Final Assembly & Inspection: Fittings, lids, and accessories installed; each drum tested for quality and performance.

Applications

Environmentally Friendly Phosphorus-Free Steel Drums are ideal for industries seeking to reduce environmental impact while maintaining high packaging performance. They are widely used in:

Chemicals & Petrochemicals: For packaging solvents, resins, surfactants, and lubricants.

Paints, Coatings & Adhesives: Excellent chemical resistance for colorants, varnishes, and emulsions.

Food & Beverage Industry: Suitable for edible oils, flavorings, and other non-corrosive materials when food-grade linings are used.

Pharmaceuticals: Safe containment of intermediate compounds and liquid formulations.

Agriculture: For eco-friendly fertilizers and biological pesticides.

Their eco-conscious production and fully recyclable materials align with the sustainability targets of many multinational companies and industries shifting toward green packaging solutions.

Quality Assurance and Testing

Sifang Group enforces strict multi-step quality control to guarantee the reliability of each phosphorus-free drum:

Coating Adhesion Test: Ensures durable bond between steel and surface coatings.

Salt Spray Corrosion Test: Verifies rust resistance over extended periods.

Leak & Pressure Test: Confirms complete sealing integrity under high pressure.

Film Thickness & Hardness Measurement: Guarantees coating uniformity and durability.

Environmental Compliance Validation: Regular third-party audits for phosphorus-free and VOC standards compliance.

Each drum undergoes 100% inspection to ensure consistency, safety, and environmental conformity before shipment.

Frequently Asked Questions (FAQ)

Q1: What makes these drums environmentally friendly?

They use phosphorus-free surface treatment and water-based coatings, eliminating pollution from phosphate sludge and VOC emissions.

Q2: Is corrosion resistance affected without phosphate treatment?

No. The phosphorus-free process provides equal or superior corrosion resistance and paint adhesion, validated through laboratory and field testing.

Q3: Can these drums be used for food or pharmaceutical products?

Yes. When equipped with FDA-approved linings (such as PVF or epoxy-phenolic), they are suitable for food and pharmaceutical applications.

Q4: Do they meet international transport standards?

Yes. They comply with UN and ISO packaging standards for both hazardous and non-hazardous goods.

Q5: Are color and logo customization available?

Yes. Sifang offers custom branding, color, and labeling to match client needs and market identity.

Conclusion

The Environmentally Friendly Phosphorus-Free Steel Drums by Wuxi Sifang Youxin Co., Ltd. combine sustainability, strength, and superior corrosion protection in one intelligent packaging solution. By replacing traditional phosphate pre-treatment with a modern, eco-safe process, Sifang provides an industrial drum that meets both performance demands and environmental responsibility.

With high structural integrity, customizable options, and compliance with international green standards, these drums are an ideal choice for global customers pursuing clean production, sustainable logistics, and circular economy packaging. Choose Sifang’s phosphorus-free drums to ensure that every product you deliver contributes to a safer, greener, and more sustainable future.