- Overview

- Recommended Products

Product Overview

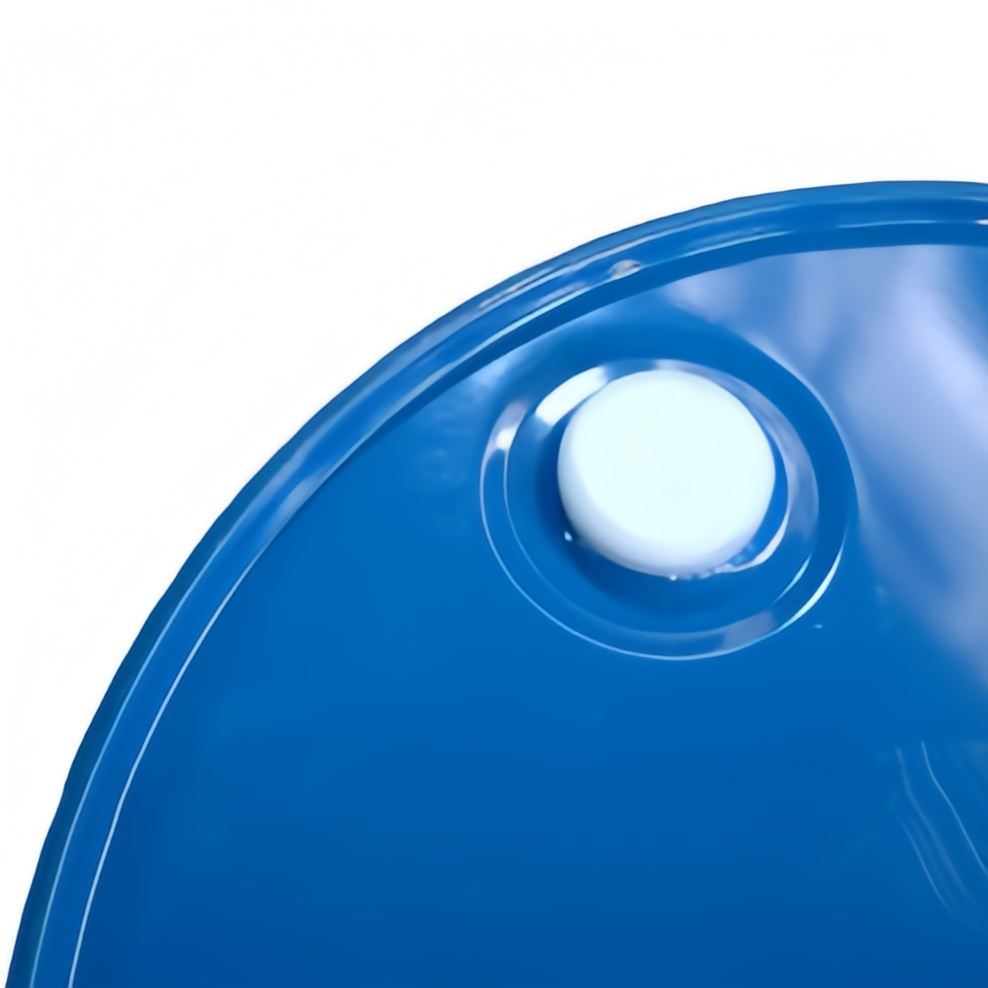

The ICI Composite Drums, developed and manufactured by Wuxi Sifang Youxin Co., Ltd., represent an advanced generation of industrial packaging solutions designed to meet the most demanding safety, durability, and chemical resistance requirements.

“ICI” refers to an integrated composite inner-lining technology, which combines the mechanical strength of a high-grade steel shell with the superior corrosion and contamination resistance of a polymer or coated interior. This hybrid structure ensures the highest performance in chemical compatibility, leak prevention, and product purity, making ICI Composite Drums the preferred choice for industries such as chemicals, coatings, food ingredients, pharmaceuticals, and specialty materials.

With a balance between structural rigidity, environmental compliance, and long-term reusability, these drums are engineered for companies seeking sustainable yet high-performance packaging solutions.

Product Specifications

Product Name: ICI Composite Steel Drum

Capacity Range: 50L – 230L (standard: 200L / 205L / 210L / 230L)

Outer Material: Cold-rolled or hot-rolled carbon steel

Steel Thickness: 0.6 – 1.2 mm (customizable)

Inner Lining Options:

Food-grade PVF (Polyvinyl Fluoride) film

PE or PP polymer liner

Epoxy phenolic or pure phenolic coating

Exterior Finish: Solvent-based, amino, or eco-friendly water-based coating

Sealing System:

Open-head type: Bolt or clamp ring closure

Closed-head type: 2” and ¾” threaded plug openings

Standard Compliance: ISO 9001, UN-approved for hazardous materials, FDA (food-grade available), RoHS, REACH

Color & Branding: Fully customizable (RAL colors, logo printing, labeling options)

Key Product Advantages

1.Hybrid Structural Integrity

The ICI Composite Drum combines a strong outer steel shell with a chemically resistant inner lining, ensuring both mechanical protection and barrier integrity even under harsh conditions.

2.Exceptional Chemical Compatibility

The inner composite layer is highly resistant to acids, alkalis, solvents, and corrosive substances, preventing metal contact and ensuring product stability during long-term storage.

3.Enhanced Safety and Leakage Prevention

The dual-layer structure and precision-sealed seams minimize leakage risks, making these drums compliant with international transport safety standards (UN-approved).

4.Superior Corrosion Resistance

Both the interior and exterior surfaces are treated with advanced coatings or composite materials to resist oxidation, moisture, and chemical attack.

5.Environmentally Sustainable Design

The inner polymer lining or water-based coatings reduce VOC emissions and allow for safe reuse or recycling, aligning with modern environmental and ESG requirements.

6.Customizable Functional Design

Available in both open-head and closed-head forms, ICI composite drums can be tailored to different product types — from viscous liquids to fine powders or food-grade materials.

Product Composition and Structure

The ICI Composite Drum features a carefully engineered multi-layer structure, integrating materials and coatings optimized for both performance and safety:

Outer Steel Body:

Constructed from precision-rolled carbon steel sheets.

Provides high strength, impact resistance, and long-term durability.

Can include parallel reinforcement rings for added rigidity.

Inner Composite Lining:

A bonded polymer film or high-performance coating applied to the drum’s interior.

Acts as a barrier layer, isolating the product from direct contact with steel.

Ensures chemical stability, purity, and extended product shelf life.

Closure System:

For open-head drums: removable lid with bolt or clamp ring, featuring a sealing gasket.

For closed-head drums: integrated top with standardized 2” and ¾” bungs for easy filling and emptying.

External Coating:

Optional solvent-based or eco-friendly waterborne coating.

Provides UV, rust, and weather protection during transport and outdoor storage.

Assembly and Manufacturing Process

Each ICI Composite Drum is produced through an advanced automated process to ensure precision and quality consistency:

Sheet Forming and Rolling → Formation of drum body and reinforcement rings.

Seam Welding and Bottom Assembly → Fully welded seams ensure leak-proof integrity.

Surface Pretreatment → Chemical cleaning and phosphor-free surface preparation.

Inner Lining Application → Composite layer or coating applied through heat bonding or electrostatic spraying.

Baking and Curing → Ensures adhesion and durability of the internal and external coatings.

Final Assembly and Quality Testing → Leak, drop, and pressure testing before packaging and shipment.

Applications

The ICI Composite Drums are widely used in high-value, high-sensitivity, and export-oriented sectors, including:

Chemical Industry: For storing solvents, resins, adhesives, and catalysts.

Paints & Coatings: Suitable for both solvent-based and water-based coatings.

Food Industry: Ideal for edible oils, flavorings, and liquid food additives (with food-grade lining).

Pharmaceuticals: For bulk active ingredients, intermediates, and sanitizing agents.

Agricultural Products: For pesticides, fertilizers, and additives.

Lubricants and Petrochemicals: For oils, greases, and specialized fluids.

Quality Assurance

All ICI composite drums from Wuxi Sifang Youxin Co., Ltd. undergo rigorous quality control and testing:

Leakage Test: 100% inspection under pressure conditions.

Drop & Impact Test: Verified in accordance with UN packaging standards.

Corrosion Test: Accelerated aging and chemical immersion tests.

Coating Adhesion Test: Ensures durable bonding between steel and composite liner.

Compatibility Testing: 6-month immersion test with customer’s product to verify chemical stability.

Frequently Asked Questions (FAQ)

Q1: What does ICI stand for?

ICI refers to “Integrated Composite Interior,” meaning the drum’s internal surface is lined with a bonded composite layer for enhanced protection.

Q2: Can these drums handle aggressive chemicals?

Yes. The composite lining is designed for strong acids, alkalis, and solvents, preventing corrosion and maintaining product purity.

Q3: Are these drums reusable?

Absolutely. The internal liner can withstand multiple cleaning cycles, allowing long-term reuse and sustainable cost efficiency.

Q4: Can I customize the color and coating type?

Yes. Both internal and external coatings are fully customizable to suit your brand and functional requirements.

Q5: Do these drums meet export standards?

Yes. They are UN-certified and compliant with ISO, FDA, and REACH international standards.

Conclusion

The ICI Composite Drums from Wuxi Sifang Youxin Co., Ltd. offer the perfect combination of mechanical durability, chemical resistance, and environmental responsibility.

With their integrated composite interior, these drums deliver unmatched performance for protecting sensitive materials from corrosion, contamination, or leakage.

Whether for chemicals, pharmaceuticals, or food applications, ICI composite drums ensure maximum safety, superior compatibility, and sustainable reusability, making them a trusted choice for global industrial packaging professionals.

Built on Sifang’s decades of expertise in steel and composite packaging, these drums represent the future of smart, secure, and eco-conscious packaging solutions.