- Overview

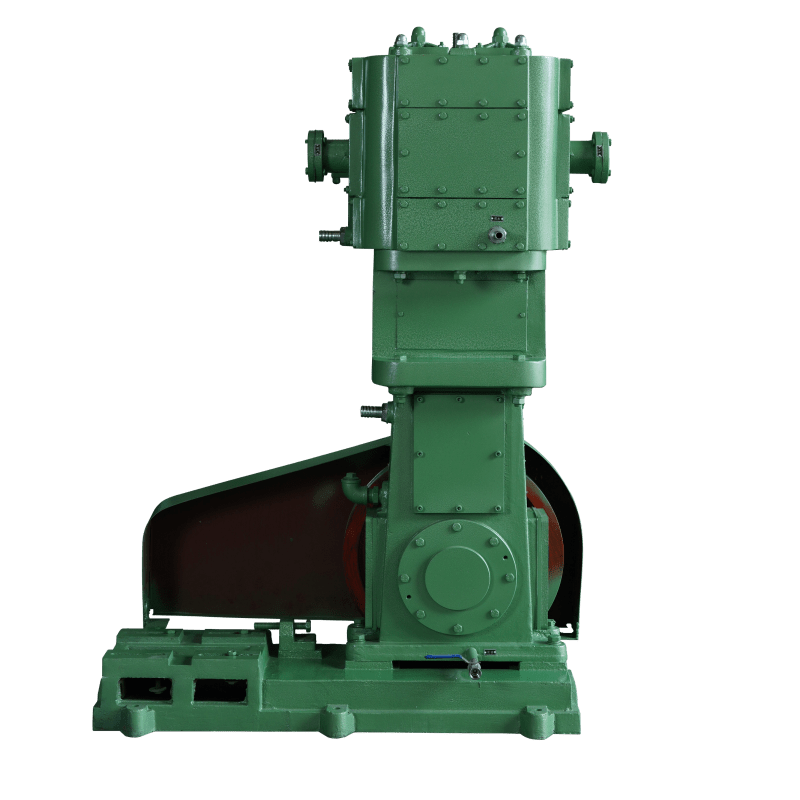

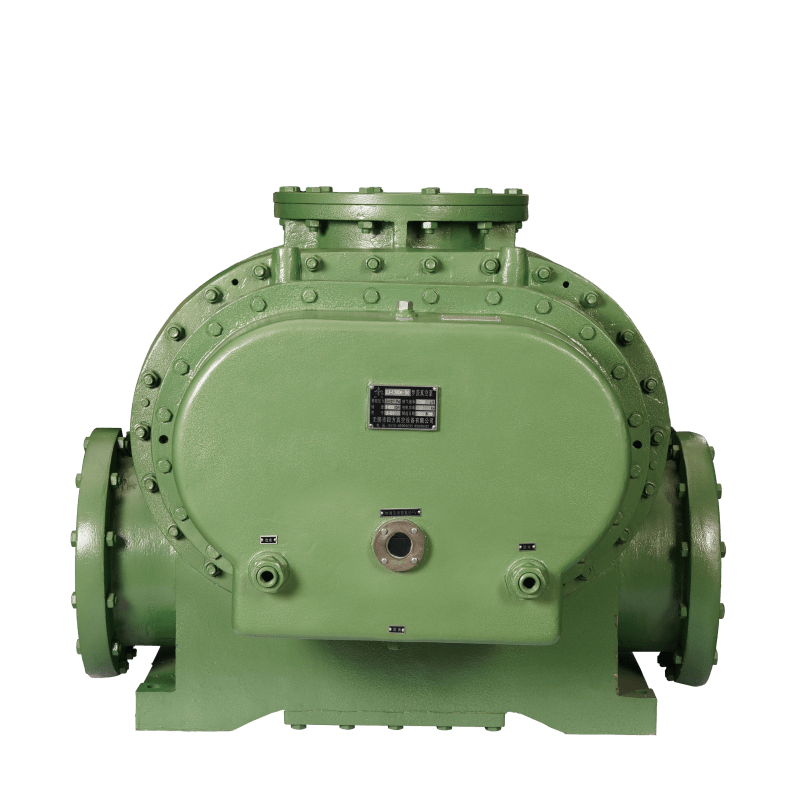

- Recommended Products

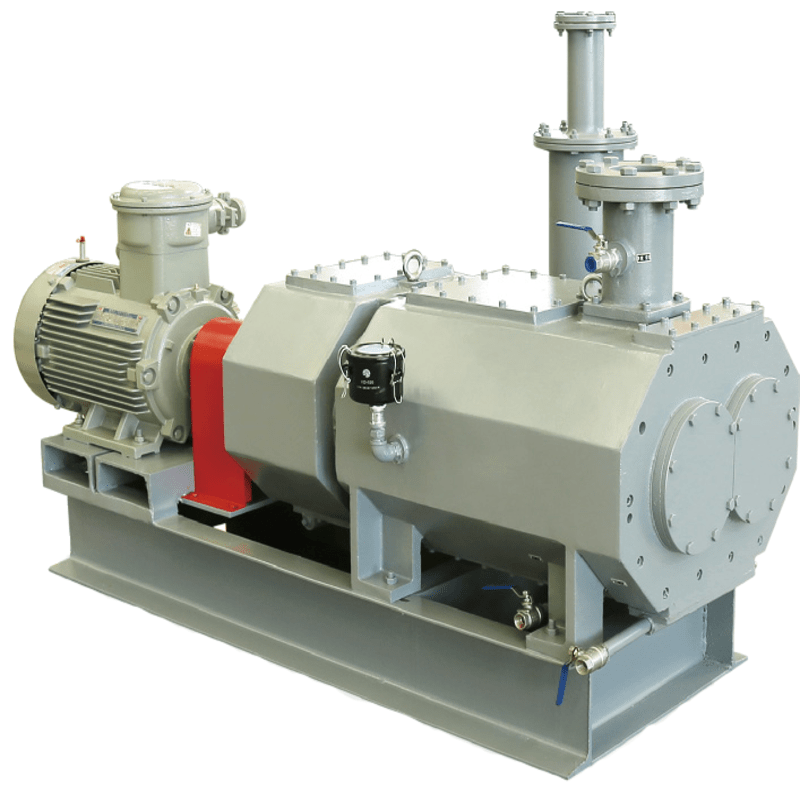

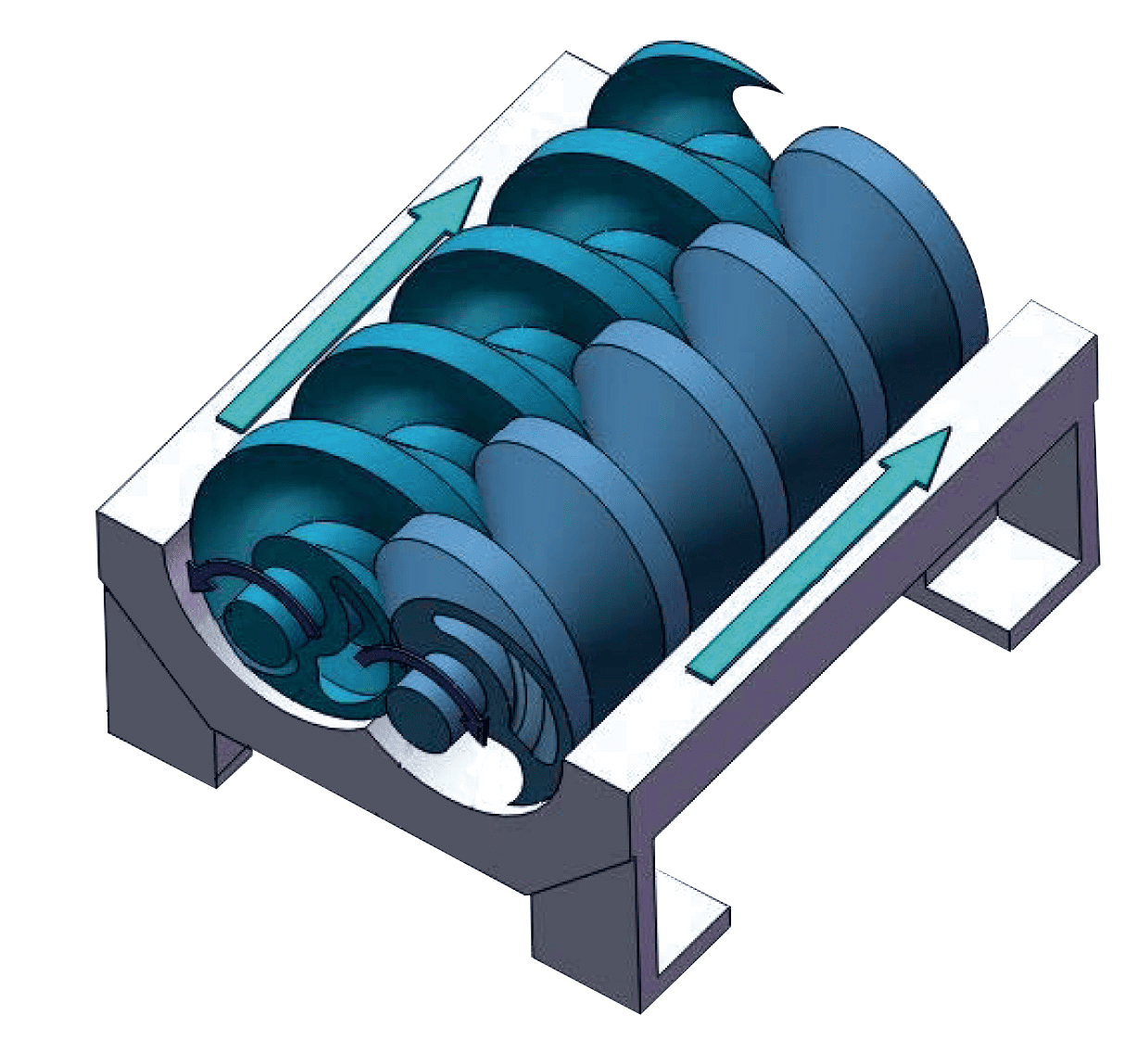

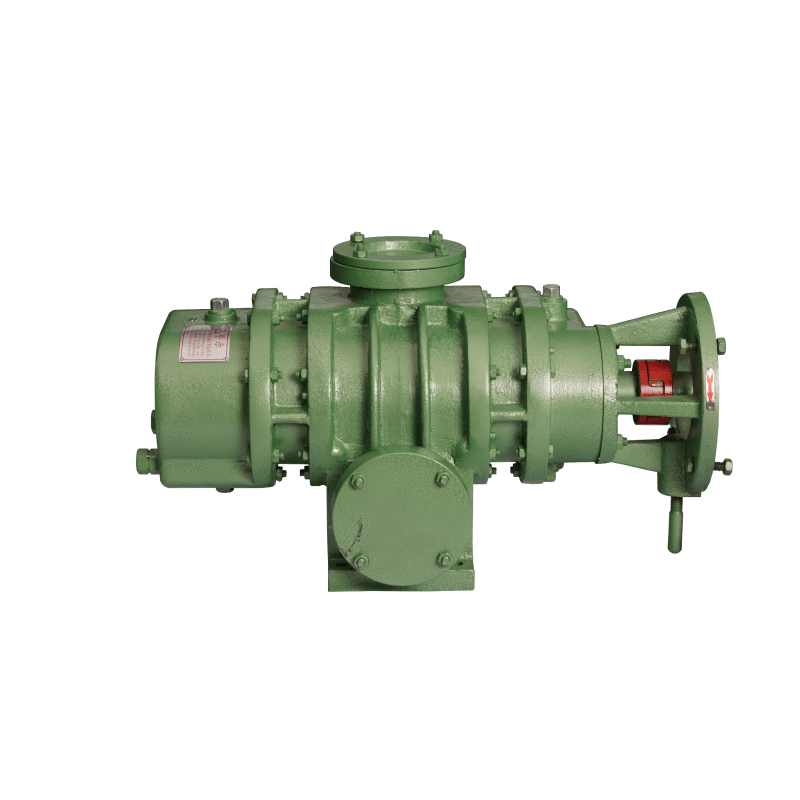

Principle description of screw vacuum pump

Screw vacuum pump is an air extraction device that uses a pair of screws to make suction and exhaust due to synchronous high-speed reverse rotation in the pump shell. Because there is a certain gap between the screws, there is no friction between the pumps, the operation is stable, the noise is low, and the working chamber does not need lubricating oil. Therefore, the dry screw pump can pump out the gas containing water vapor and a small amount of dust. Industry Applications The ultimate pressure of LGB screw vacuum pump can reach 5pa, which is widely used in chemical industry, metallurgy, electronics, petroleum, aerospace, tools, papermaking, packaging, food, medicine, medical devices, information engineering, bioengineering, microelectronics and other fields.

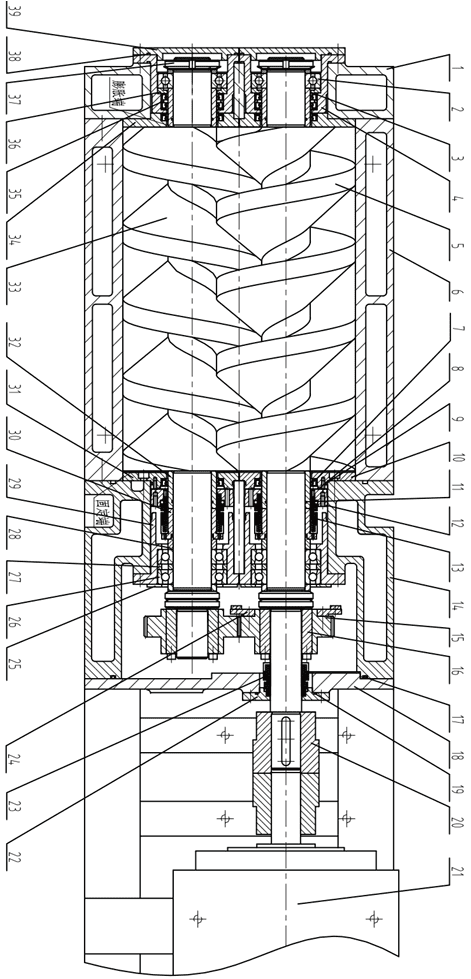

Screw pump features

1. Clean vacuum can be obtained without any medium in the working chamber.

2. It can run at high speed after high-precision dynamic balancing and has no friction between rotating parts, so it has a long service life.

3. Gas is not compressed in the pump, suitable for extracting condensable gas;

4. Single pump can work in a wide range and be pumped from atmospheric pressure to less than 100Pa.

5. The working chamber and the surface of the screw rotor can be preserved to adapt to the harsh conditions.

6. Compared with oil-sealed mechanical vacuum pump, condensable substance will not stay in the pump, no oil and gas and oil mist emission, environmental protection is preferred;

7. Compared with liquid ring pump, only circulating cooling water is needed, and the extracted gas is not in contact with water, avoiding the influence of water temperature on vacuum, material is easy to recover, wastewater treatment can be omitted, and the limit pressure is lower, so screw Roots unit is more efficient to obtain vacuum.

|

Model Function |

LGB-30 | LGB-50 | LGB-70 | LGB-100 | LGB-150 | LGB-200 | LGB-300 | LGB-450 | LGB-600 | LGB-70 | LGB-100 | LGB-200 | LGB-300 |

| Pumping speed (L/S) | 30 | 50 | 70 | 100 | 150 | 200 | 300 | 450 | 600 | 70 | 100 | 200 | 300 |

| Ultimate pressure (Pa) | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 |

| rotational speed (rpm) | 2840 | 2920 | 2900 | 2940 | 2940 | 2980 | 2980 | 2980 | 2980 | 2900 | 2940 | 2940 | 2950 |

| Connections of inlet (DN) | 50 | 50 | 80 | 80 | 100 | 125 | 125 | 150 | 150 | 50 | 80 | 100 | 125 |

| Connections of outle (DN) | 25 | 40 | 50 | 50 | 65 | 65 | 65 | 100 | 100 | 45 | 65 | 65 | 80 |

| Noise level dB(A) | ≤68 | ≤70 | ≤71 | ≤72 | ≤72 | ≤75 | ≤78 | ≤80 | ≤80 | ≤80 | ≤80 | ≤80 | ≤80 |

| temperature rise (°C ) | ≤40°C | ≤40°C | ≤40°C | ≤40°C | ≤40°C | ≤40°C | ≤40°C | ≤40°C | ≤40°C | ≤40°C | ≤40°C | ≤40°C | ≤40°C |

| Pumping size (mm) | 810X315X396 | 1120X480X720 | 1500X630X810 | 1700X630X810 | 1360X960X700 | 1650X847X933 | 1740X960X980 | 2100X1100X1030 | |||||

| Weight with oil filling (KG) | 160 | 320 | 380 | 400 | 800 | 1000 | 1100 | 1800 | 2000 | 500 | 665 | 1020 | 1300 |

| Motor Power (KW) | 2.2 | 4 | 5.5 | 7.5 | 11 | 15 | 22 | 30 | 37 | 7.5 | 15 | 18.5 | 37 |

| Motor Voltage/motor base frequency (V/Hz) | 380/50 | 380/50 | 380/50 | 380/50 | 380/50 | 380/50 | 380/50 | 380/50 | 380/50 | 380/50 | 380/50 | 380/50 | 380/50 |

| Nominal Motor speed (rpm) | 2840 | 2920 | 2900 | 2940 | 2940 | 2980 | 2980 | 2980 | 2980 | 2900 | 2940 | 2940 | 2950 |

| Nominal Motor current (A) | 4.8 | 8.1 | 11.1 | 14.8 | 21.6 | 28.8 | 41 | 55.5 | 67.9 | 14.8 | 28.8 | 35.5 | 67.9 |

| Type of protection (IP) | IP55 | IP55 | IP55 | IP55 | IP55 | IP55 | IP55 | IP55 | IP55 | IP55 | IP55 | IP55 | IP55 |

Company Strength Introduction

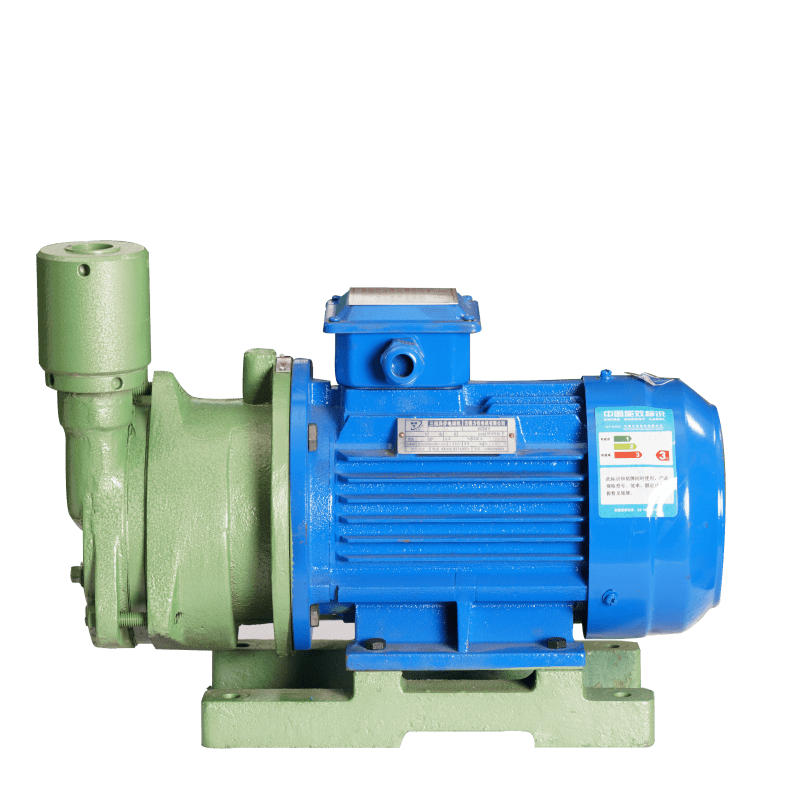

Our company is one of the largest manufacturing enterprises of vacuum obtaining equipment in China. The company always adheres to the working attitude of "Professional & Precision" to constantly increase the technological content of products, as well as the developments and innovations of products. At present, there are vacuum pumps of rotary vane series (2X, XD), water ring series (SZ, 2SK, SK, 2BE), reciprocating series (WLW), roots series (ZJ) of nine specifications, roots-water ring units (JZJS), roots-rotary vane unit (JZJX), roots- reciprocating pump unit (JZJW), and other products, which are widely used in metallurgy, chemical industry, medicine, textile, food, aviation, electronic, scientific research and other industries and sections.

Our company has a strong technical force, and a professional team for the design and manufacture of vacuum obtaining equipment. In addition, we keep close cooperative relationships with domestic and foreign scientific research institutes, universities and colleges, and have advanced product technologies, good performances and perfect services. With decades of R&D and manufacturing experience in vacuum obtaining equipment, we have trained an experienced team in production and technical services to ensure that we provide our users with high-quality products and excellent services. We pursue the "Ease & Convenient" as our service tenet, and through the continues efforts of our all staff, Sifang Vacuum Equipment Co., Ltd. will create the greatest value and return for you.

Notes in choosing vacuum pump

- The limit pressure of vacuum pump shall meet this technology's working pressure. In general, the limit pressure shall one order of magnitude lower than technological requirements

- Each pump has a certain working pressure range. Thereafter, the working point of pump shall be within this range. It can not work for a long time beyond the allowable working pressure.

- Under the working pressure, the vacuum pump shall discharge all gas generated during technological process in the vacuum device.

- Choose the vacuum unit:

(1) When use one pump which can not satisfy the suction and vacuum demands, shall combine several pumps and they can complement each other and then can meet the technological requirements.

(2) Some vacuum pumps can not work under the atmospheric pressure, shall need forevacuum. Some vacuum pumps discharge pressure is lower than atmospheric pressure, shall need backing pump, thereafter, they are combined for use. The pumps which are combined are called vacuum pump unit which makes the vacuum system gets good vacuum degree and discharge amount. Because different vacuum pump needs different demands for discharged gas, e.g. in normal condition, Roots—sliding unit is not available for the gas contained much coagulate gas, we shall choose correctly the combined vacuum pump.

- When you choose the oil sealed pump, you shall first know that if your vacuum needs the demand for the oil pollution or not. If the device needs no oil strictly, you shall choose various no oil pumps, such as: water ring pump, low temperature pump. If the demand is not strict, can choose the oil pump and adds some oil pollution protection measures, e.g. adds cold trap, oil protection trap, baffle, etc which can reach cleaning vacuum demands.

- Know the discharged gas component. Inspect the gas if it contains the coagulate vapor, particle, dust or it is corrosive or not. When choose the vacuum pump, shall know the gas component and choose the proper pump according to the discharged gas. If the gas contained the vapor, particle and corrosive gas, shall consider installing the auxiliary equipment in the air inlet pipe of the pump such as: condenser, dust collector.

- When choose the oil sealed vacuum pump, shall consider the effect to the environment by the oil vapor discharged from vacuum pump. If the oil vapor shall not allow the pollution, shall choose the non oil vacuum pump or discharge the vapor out of the room.

- The vibration generated during the vacuum working affects the technological process and environment or not. If the technological process does not allow, shall choose the non vibration pump or take the vibration proof measures.

- The price, operation and maintenance cost of vacuum pump

Taking into account all above conditions, decide a proper solution for you.

(1) Lowest investment cost.

(2) Lowest production operation cost

(3) Feasible solution after considering above two conditions

The best working range for vacuum pump

Pump type |

oil sealed mechanical pump |

water steam jet ejector |

Roots pump |

oil booster pump |

oil diffusion pump |

Optimal working range (Pa) |

10²–10 |

10⁵–10² |

10²–1 |

1–10⁻¹ |

5×10⁻²–10⁻⁴ |

Laws and formulas

1. Fore pumping speed of Roots pump

S=(0.1~0.2)S{Roots}

2. Pumping speed selection of roughing vacuum pump

S=Q1/P{forepumping}

S=2.3Kq* V*lg(Pa/P{forepumping}/t

- Effective pumping speed of mechanical pump (L/s)

- Effective pumping speed of Roots pump (L/s)

- Leakage rate of vacuum system (Torr-L/s)

- Forevacuum degree needs to reach to (Torr)

- Volume of vacuum system (L)

- Time required for reaching to P{Forepumping}.

- Atmospheric pressure (Torr)

- Those related to pressure P under correction coefficients and equipment terminal values