- Overview

- Recommended Products

Product Overview

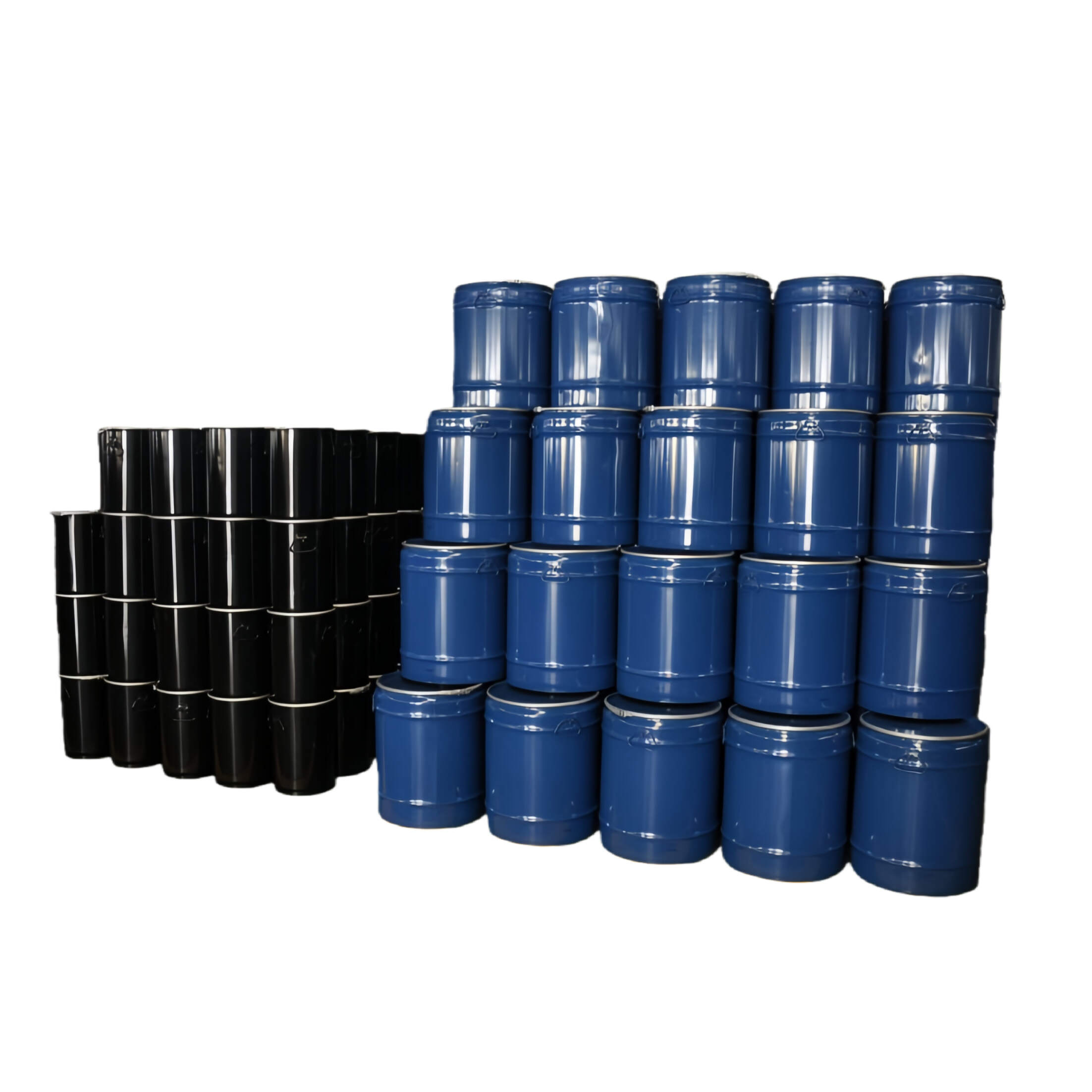

Wuxi Sifang Youxin Co., Ltd. is a leading manufacturer of high-quality industrial packaging solutions in China. Our 200L, 205L (φ567), 210L, and 230L Mouth Open Metal Barrels are specifically designed for the safe storage and transportation of solid, semi-solid, and viscous materials. Featuring robust steel construction, customizable coatings, and reliable sealing systems, these open-top drums provide maximum protection, flexibility, and reusability for a wide range of industrial applications.

Product Specifications

Capacity: 200L / 205L (φ567) / 210L / 230L

Type: Open head (removable lid) metal barrel

Material: High-strength cold-rolled steel

Thickness: 0.8 – 1.2 mm (customizable)

Diameter: 567 mm (for 205L standard type)

Height: Adjustable according to required capacity

Surface Finish: External amino or water-based coating; internal phenolic epoxy, pure phenolic, or PVF coating available

Closure System: Removable lid with sealing gasket and lock ring (lever or bolt type)

Color: Customizable upon request

Volume Tolerance: ±1%

Key Product Advantages

1.High Strength and Durability

The drum body is manufactured using advanced rolling and automatic seam welding technology, ensuring exceptional strength and durability. Reinforced rolling ribs prevent deformation during handling, stacking, and filling operations.

2.Convenient Access and Reusability

The open-mouth design allows easy filling, emptying, and cleaning—ideal for products that require manual or mechanical access during production and usage. The barrels can be reused multiple times, reducing packaging costs and environmental impact.

3.Flexible Coating Solutions

Exterior Coating: Optional amino or eco-friendly water-based coatings, providing excellent corrosion resistance and weather durability.

Interior Lining: Optional PVF, epoxy-phenolic, or pure phenolic coatings that ensure chemical compatibility and long-term corrosion protection for various materials.

4.Secure Closure System

Each drum lid is equipped with a precision-engineered gasket and a locking ring (available in lever or bolt type), ensuring tight sealing and leak-proof performance. This structure provides both safety and convenience during filling and transport.

5.Customization and Branding Options

Sifang offers full customization including color, logo printing, labeling, and special closures to meet specific customer or regulatory requirements.

6.Environmentally Compliant Manufacturing

Water-based coatings are available to meet environmental and health safety standards, reducing VOC emissions and aligning with international sustainability policies.

Product Composition and Assembly

Each open-head metal barrel consists of the following major components:

Drum Body: Made of cold-rolled steel sheet, precisely formed and welded to ensure strength and leak resistance.

Top Cover (Lid): Removable lid with sealing gasket, designed for easy opening and closing.

Bottom Plate: Seam-welded bottom ensures excellent structural integrity and load-bearing capacity.

Lock Ring: Available in bolt-type or lever-type for secure closure and easy operation.

Coating Layers: Applied through automated spray or electrostatic process and oven-baked for maximum adhesion and corrosion resistance.

All assembly and finishing operations are carried out on fully automated production lines to guarantee consistency and quality across every unit.

Applications

The Mouth Open Metal Barrels are suitable for a broad range of industries, including:

Chemical Industry: For storing and transporting resins, adhesives, and powder chemicals.

Paints and Coatings: Ideal for high-viscosity products like paints, inks, and pigments.

Food Industry: Suitable for food-grade materials such as edible oils, flavoring ingredients, and syrups (with appropriate internal coating).

Pharmaceuticals and Agriculture: Used for bulk packaging of raw materials, intermediates, and agricultural chemicals.

Recycling and Waste Management: Commonly used for hazardous waste collection, cleaning agents, and reconditioning.

These barrels are compatible with both manual and automated filling systems and can be stacked efficiently for optimized warehouse storage.

Quality Assurance and Testing

Every Sifang open-head barrel undergoes comprehensive quality inspection and performance testing:

Leakage and Pressure Testing

Drop and Impact Resistance Tests

Coating Adhesion and Corrosion Testing

Immersion Compatibility Tests for chemical and product stability

Dimensional and Appearance Inspection

With a total annual production capacity exceeding 12 million units across our factories in Wuxi, Nanjing, Taicang, and Jiaxing, we ensure consistent quality, flexible order handling, and timely global delivery.

Frequently Asked Questions (FAQ)

Q1: What is the difference between open and closed metal barrels?

Open-head barrels are designed for solid or semi-solid materials, featuring a removable lid for easy filling and cleaning, while closed-head barrels are ideal for liquids.

Q2: Can you provide customized lid or ring types?

Yes, both lever-type and bolt-type lock rings are available. We can also provide specific gasket materials according to your product’s chemical characteristics.

Q3: How long does the internal coating last?

Depending on the coating type and storage conditions, the protective lining can last for years. We offer compatibility tests to ensure the selected coating suits your product.

Q4: What is your standard delivery time?

Generally, delivery takes 2–4 weeks after order confirmation, depending on order volume and customization details.

Conclusion

The 200L / 205L (φ567) / 210L / 230L Mouth Open Metal Barrels from Wuxi Sifang Youxin Co., Ltd. combine durability, safety, and versatility for modern industrial packaging needs. Designed for both efficiency and sustainability, these drums deliver optimal protection for your materials while meeting international quality standards. Backed by Sifang’s strong production capability, technical expertise, and commitment to customer satisfaction, our open-mouth barrels are the reliable choice for global partners in chemical, coating, food, and manufacturing industries.