- Overview

- Recommended Products

Product Overview

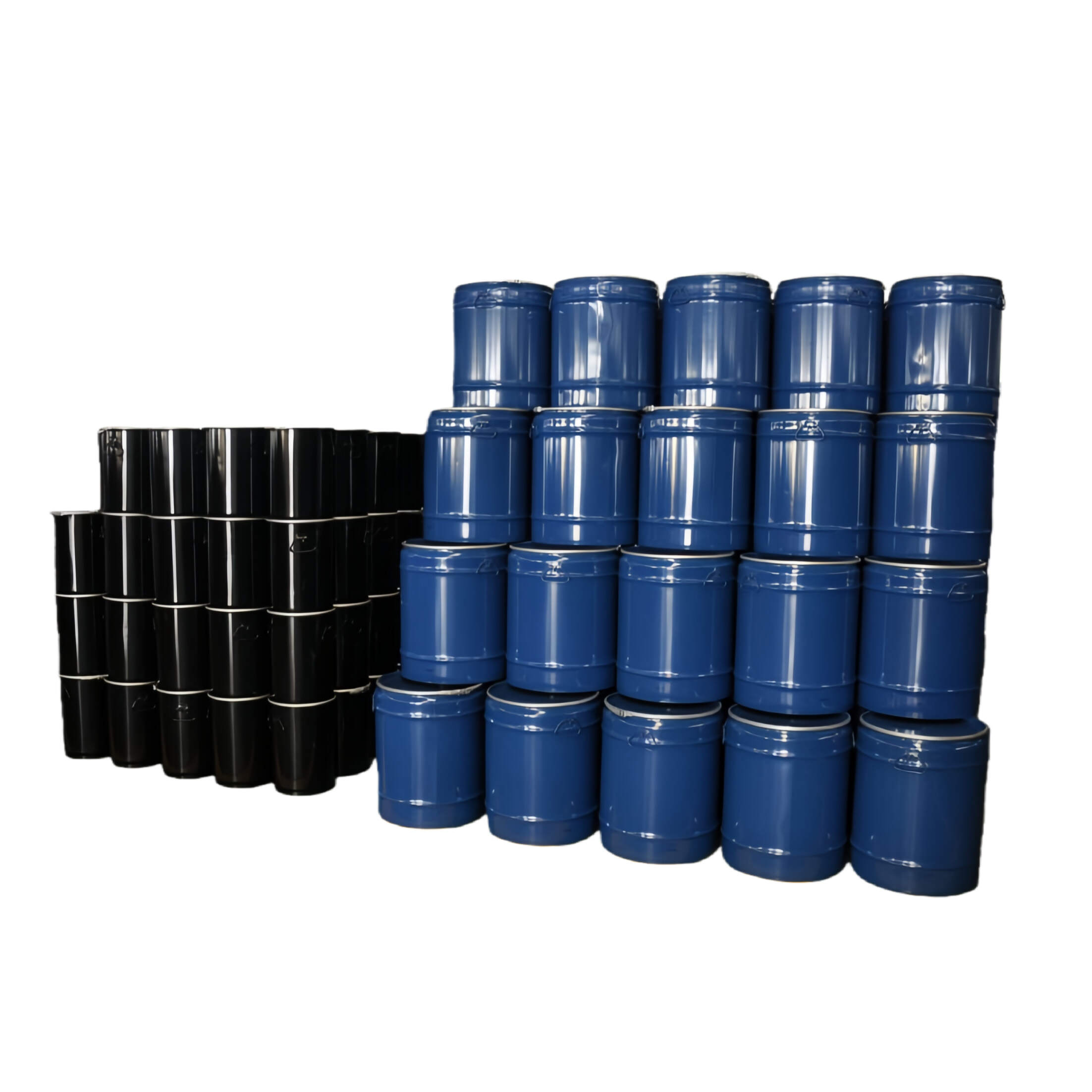

Wuxi Sifang Youxin Co., Ltd. is one of China’s largest and most professional manufacturers of industrial steel packaging. Our 200L, 210L, and 230L Mouth Closed Metal Barrels are designed for safe and efficient storage and transportation of liquid and semi-liquid products across multiple industries. Built with precision engineering and advanced coating technologies, these drums ensure high durability, chemical resistance, and leak-proof performance, making them a trusted choice for chemical, petrochemical, lubricant, and food-grade applications.

Product Specifications

Capacity: 200L / 210L / 230L

Type: Closed head (tight head) metal barrel

Material: High-quality cold-rolled steel

Thickness: 0.8 – 1.2 mm (customizable)

Surface Treatment: External amino or water-based paint; internal phenolic epoxy, fluoropolymer (PVF), or epoxy powder coating available

Top Openings: 2” and 3/4” threaded bung holes

Sealing: Fully welded seams, triple-seam chimes for maximum leak protection

Colors: Customizable according to customer or brand requirements

Volume Tolerance: ±1%

Key Advantages

1.Superior Structural Integrity

Each drum is produced with precision rolling and automatic welding equipment to ensure high strength, uniform wall thickness, and resistance to deformation under pressure. Reinforcing ribs on the barrel body effectively prevent expansion or rupture during filling and transport.

2.Comprehensive Coating Options

Exterior Coatings: Standard amino coatings or eco-friendly water-based coatings that provide excellent corrosion resistance, weather durability, and smooth surface appearance.

Interior Linings: Optional PVF, epoxy-phenolic, pure phenolic, or epoxy powder coatings that resist chemical corrosion, ensuring compatibility with acids, solvents, lubricants, and food products.

3.High Adaptability and Customization

Available in multiple capacities and configurations to meet diverse product requirements. Logo printing, color customization, and specialized closures can be tailored according to client needs.

4.Environmental and Safety Compliance

All coatings comply with environmental and food safety standards. Water-based paint options reduce volatile emissions, aligning with global sustainability regulations.

5.Reliable Sealing and Leak-Proof Performance

The precision-machined 2” and 3/4” bung holes with tight-sealing gaskets ensure secure closure and excellent liquid containment, minimizing the risk of leakage during long-distance transport.

Product Composition and Assembly

Each closed head steel drum consists of:

Drum Body: Cold-rolled steel sheet formed by high-precision rolling and automatic seam welding.

Drum Top & Bottom: Pressed steel ends with reinforced ribs for enhanced strength.

Openings: Standard 2” and 3/4” threaded bungs with optional vent holes.

Coating Layers: Interior and exterior coatings applied by electrostatic or spray process, then baked for durability.

Assembly Process: Fully automated production line ensures consistent welding, painting, and drying quality for every unit.

Applications

Our closed metal barrels are widely used in:

Chemical Industry: Storage and transport of solvents, resins, adhesives, and additives.

Petrochemical Sector: Packaging of lubricating oils, synthetic oils, and fuel additives.

Paint and Coatings: Safe containment for paints, varnishes, and thinners.

Food & Flavoring: Suitable for edible oils, flavor concentrates, and syrup storage (with food-grade inner coatings).

Pharmaceutical & Agricultural: Reliable containment for intermediates, pesticides, and pharmaceutical chemicals.

These drums are compatible with automated filling and palletizing systems, improving operational efficiency in large-scale industrial use.

Quality Assurance and Testing

Each barrel undergoes rigorous quality inspection including:

Hydraulic pressure testing

Drop resistance testing

Leakage inspection

Coating adhesion test

Compatibility and immersion tests (over 6 months for customized coatings)

With an annual production capacity exceeding 12 million units across four major production bases in Wuxi, Nanjing, Taicang, and Jiaxing, Wuxi Sifang Group guarantees stable supply, quick delivery, and consistent quality.

Frequently Asked Questions (FAQ)

Q1: Can you provide customized colors or logos?

Yes, both color and branding customization are available according to your specifications.

Q2: What type of coating is suitable for my product?

Our engineers can recommend the best internal coating based on your product’s chemical properties. We also offer sample immersion tests for compatibility confirmation.

Q3: What is the minimum order quantity (MOQ)?

MOQ can be negotiated based on product type and delivery requirements. We support both large-scale and small-batch orders.

Q4: How do you ensure product safety during shipment?

All drums are stacked with protective wrapping and reinforced strapping to prevent deformation or scratching during transportation.

Conclusion

The 200L / 210L / 230L Mouth Closed Metal Barrels from Wuxi Sifang Youxin Co., Ltd. deliver a robust, eco-friendly, and customizable packaging solution for modern industries. With over 20 years of manufacturing expertise, advanced coating technology, and a customer-oriented philosophy, Sifang ensures every drum meets the highest standards of safety, durability, and performance — making it the preferred choice for global partners in chemical, petrochemical, and food sectors.