- Overview

- Recommended Products

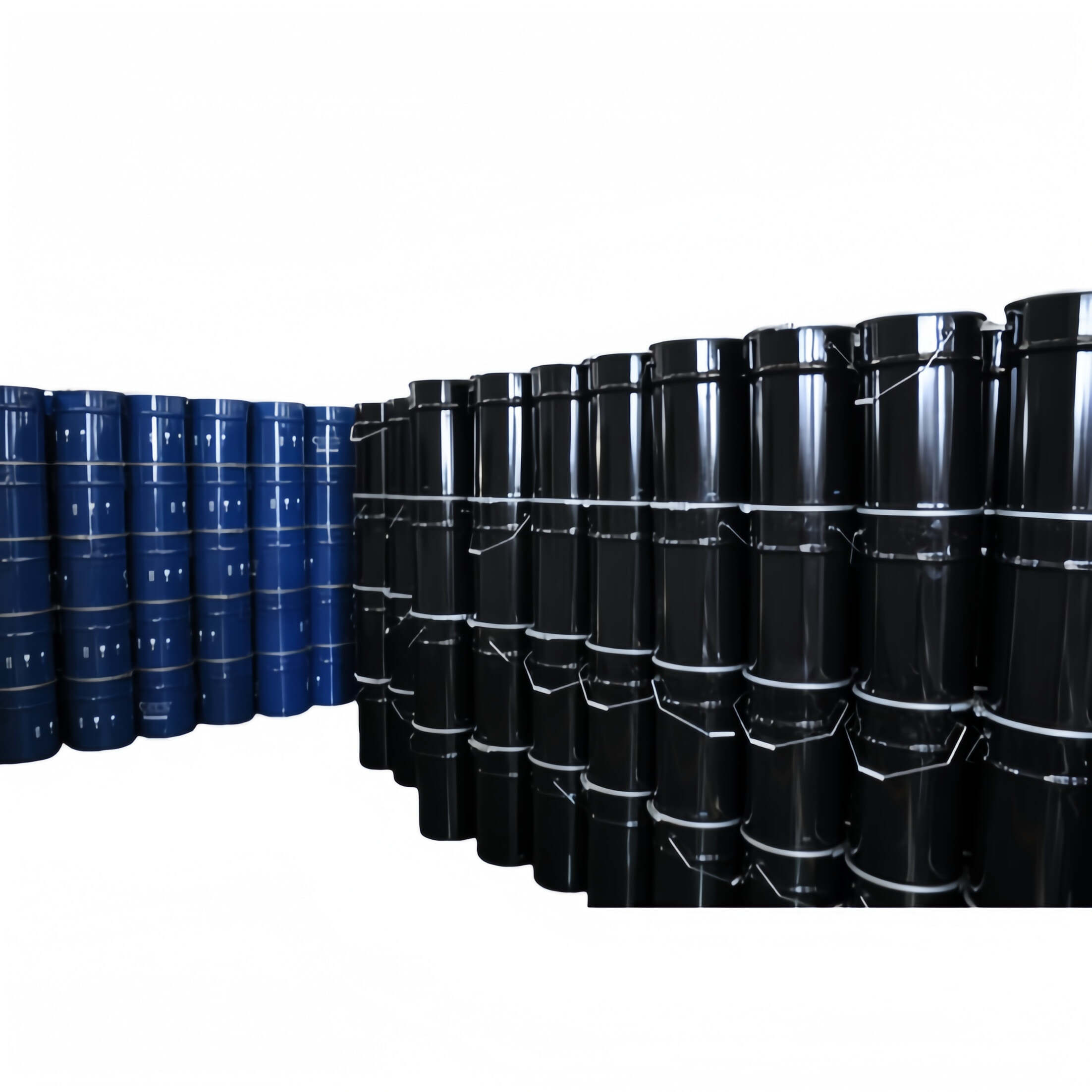

Product Overview

The Epoxy Phenolic and Pure Phenolic Coatings Steel Drums manufactured by Wuxi Sifang Youxin Co., Ltd. are designed to provide superior chemical resistance, durability, and product purity for industrial packaging applications. These drums are coated internally with high-performance epoxy phenolic or pure phenolic linings, ensuring reliable containment of chemicals, solvents, food-grade materials, and other reactive or high-purity substances.

With a focus on safety, longevity, and contamination control, Sifang’s coating technology combines advanced resin formulations and precision-controlled baking processes to deliver a strong, uniform protective film inside the drum. The result is a packaging solution that meets the most demanding performance standards across chemical, food, pharmaceutical, and coating industries.

Product Specifications

Type: Open-head or closed-head steel drums with epoxy phenolic or pure phenolic internal coating

Capacity Range: 50L – 230L (standard capacities: 200L, 205L, 210L, 230L)

Material: Premium cold-rolled or hot-rolled carbon steel

Thickness: 0.6 mm – 1.2 mm (customizable per user requirements)

Surface Treatment

External - Water-based or amino baking enamel (custom colors available)

Internal - Epoxy phenolic or pure phenolic coatings (baked finish)

Coating Thickness: 20–35 μm, uniform application for consistent protection

Sealing Type: Seamed or welded closure, with 2” and ¾” threaded openings (for closed drums)

Standards: Complies with UN, ISO, and international hazardous materials packaging regulations

Key Product Advantages

1.Exceptional Chemical Resistance

The epoxy phenolic and pure phenolic linings provide excellent protection against a wide range of chemicals, including acids, alkalis, solvents, and alcohols. They prevent corrosion and chemical reaction between drum walls and the stored contents, ensuring material stability and purity.

2.High Temperature and Pressure Resistance

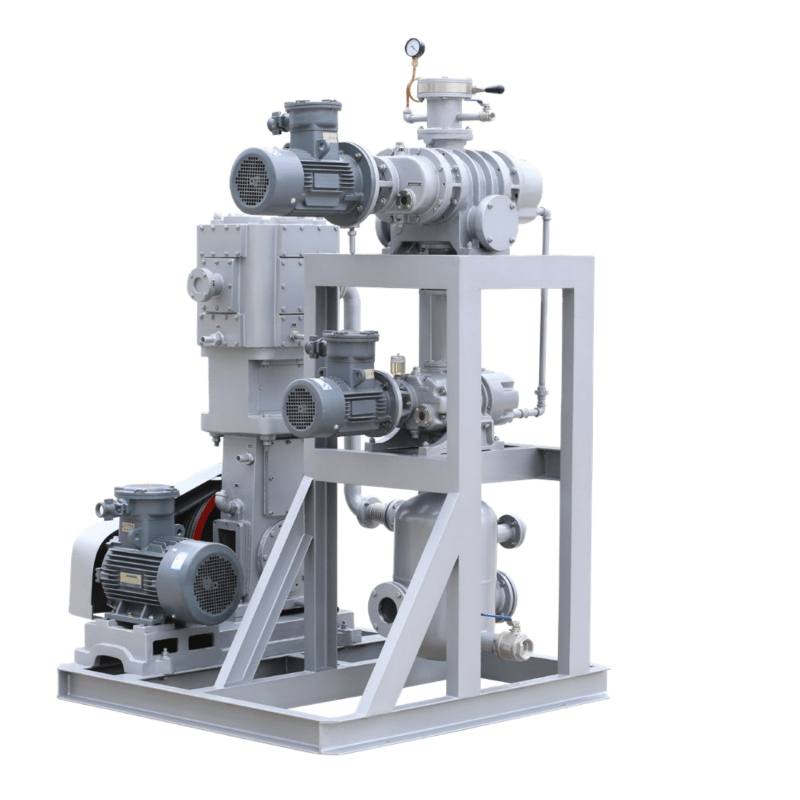

These coatings are thermally cured at high temperatures, producing a dense, cross-linked structure that withstands both high heat and internal pressure. This ensures performance integrity even under demanding transport and storage conditions.

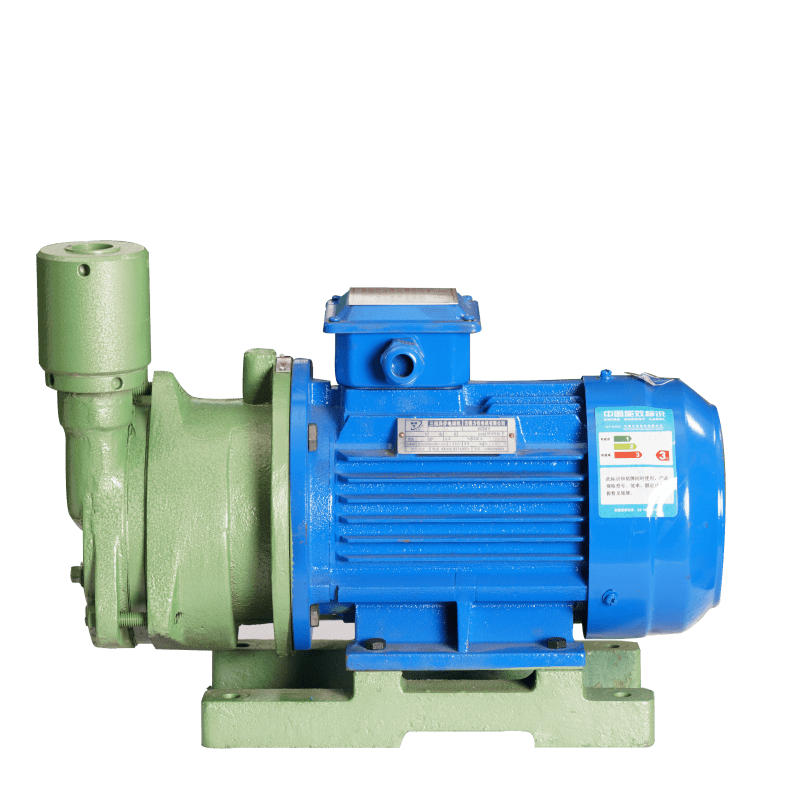

3.Superior Adhesion and Coating Uniformity

Using advanced electrostatic and spray coating systems, Sifang ensures a uniform layer thickness with excellent adhesion to the steel substrate, preventing blistering, peeling, or delamination during use.

4.Dual Coating Options for Different Applications

Epoxy Phenolic Coating: Ideal for general chemical, lubricant, and resin products requiring balanced chemical resistance and flexibility.

Pure Phenolic Coating: Best suited for strong solvents, alcohols, and highly reactive chemicals needing maximum corrosion resistance and high purity.

5.Food-Grade and Pharmaceutical Compatibility

Both coatings can be formulated to meet FDA and EU food contact safety standards, making them suitable for edible oils, flavorings, and pharmaceutical intermediates.

6.Extended Service Life and Reusability

The durable coatings enhance corrosion protection, extending drum lifespan and enabling multiple reuse cycles without compromising internal surface performance.

Product Composition and Structure

1.Each Epoxy Phenolic and Pure Phenolic Coatings Steel Drum is composed of:

Drum Body: Straight or slightly constricted steel shell, precision-rolled and welded.

Top and Bottom Ends: Seam-welded with leak-proof construction.

Internal Lining

Epoxy Phenolic: Blend of epoxy and phenolic resins for balanced flexibility and chemical resistance.

Pure Phenolic: 100% phenolic resin formulation offering exceptional solvent resistance and hardness.

External Coating: Durable amino or water-based paint to protect against environmental exposure.

Fittings and Closures: Standard 2” and ¾” bungs for closed drums or clamp rings for open-head models.

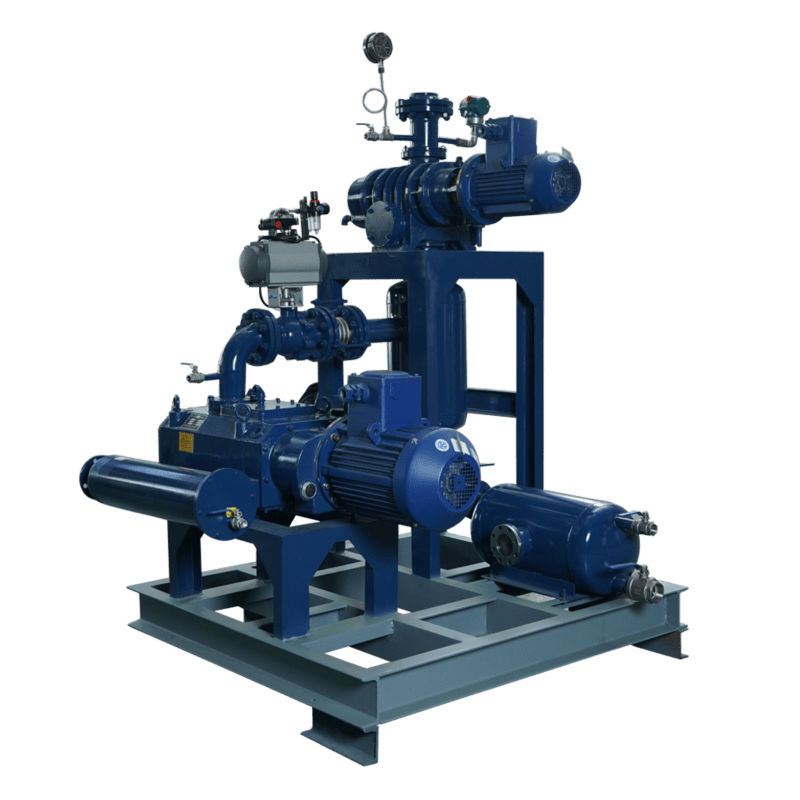

2.Coating Process Steps

Surface Preparation: Degreasing and cleaning to remove contaminants.

Coating Application: Automated spraying or electrostatic deposition for uniform coverage.

Curing and Baking: High-temperature polymerization to ensure coating hardness and adhesion.

Inspection: Film thickness, gloss, adhesion, and corrosion resistance tests to ensure consistent quality.

Applications

These Epoxy Phenolic and Pure Phenolic Coatings Steel Drums are suitable for various industries requiring chemical stability and product purity:

Chemical & Petrochemical: Solvents, resins, catalysts, lubricants, and high-purity chemicals.

Paints & Coatings: Storage of varnishes, inks, and pigments sensitive to contamination.

Pharmaceutical & Food: Safe containment of liquid ingredients, syrups, and edible oils.

Agriculture: Fertilizers and pesticides requiring chemical-resistant packaging.

Energy & Lubricants: For oils, additives, and hydraulic fluids exposed to temperature variations.

Their inner coatings act as a barrier against corrosion and chemical attack, ensuring the product retains its original quality, color, and chemical composition throughout storage and transport.

Quality Assurance and Testing

Wuxi Sifang Youxin employs a rigorous multi-stage quality control system to ensure every coated drum meets international standards:

Coating Thickness & Adhesion Test: Ensures consistent protective film and strong adhesion.

Chemical Resistance Test: Evaluates coating stability with representative samples of customer products.

Salt Spray & Humidity Test: Simulates long-term exposure to ensure corrosion resistance.

Leakage & Pressure Testing: Each drum is pressure-tested to guarantee airtight sealing.

Visual & Surface Inspection: Confirms coating uniformity and flawless finish.

Each production batch is traceable, and test records are maintained to support client audits and regulatory compliance.

Frequently Asked Questions (FAQ)

Q1: What is the difference between epoxy phenolic and pure phenolic coatings?

Epoxy phenolic coatings balance flexibility and corrosion resistance, while pure phenolic coatings provide maximum solvent and chemical resistance but are more rigid.

Q2: Can these coatings be used for food or pharmaceutical products?

Yes. When produced under FDA or EU compliance conditions, they are safe for food and pharmaceutical applications.

Q3: What is the typical lifespan of the coating?

Under normal storage and handling, the coating maintains integrity for over five years, depending on product compatibility and storage conditions.

Q4: Are the coatings suitable for acidic and alkaline materials?

Yes. Both coatings offer strong protection against mild to moderate acids and bases; pure phenolic is recommended for stronger chemicals.

Q5: Can the drum color and branding be customized?

Absolutely. Sifang provides customization for external color, logo printing, and labeling according to customer specifications.

Conclusion

The Epoxy Phenolic and Pure Phenolic Coatings Steel Drums by Wuxi Sifang Youxin Co., Ltd. deliver exceptional chemical protection, durability, and product purity for demanding industrial and commercial applications. Through advanced coating formulations and precision manufacturing, these drums ensure long-lasting performance, safety, and sustainability in every use.

With Sifang’s commitment to quality, innovation, and environmental responsibility, these coated steel drums have become a trusted choice among global chemical, food, and pharmaceutical producers. Whether your priority is corrosion resistance, purity, or compliance, Sifang’s epoxy phenolic and pure phenolic coated drums provide the ultimate solution for reliable, clean, and efficient packaging.