- Overview

- Recommended Products

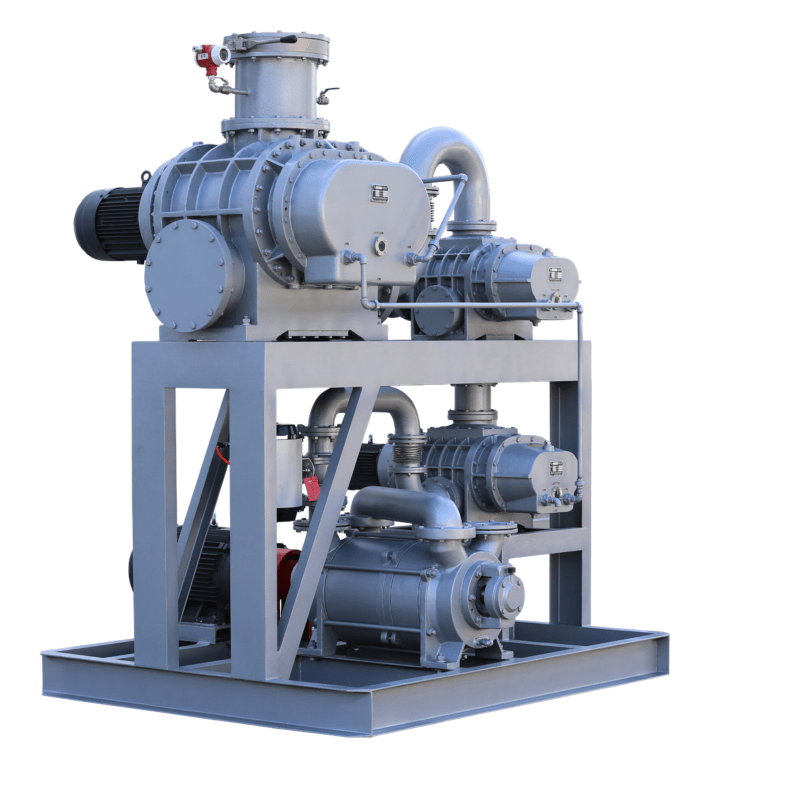

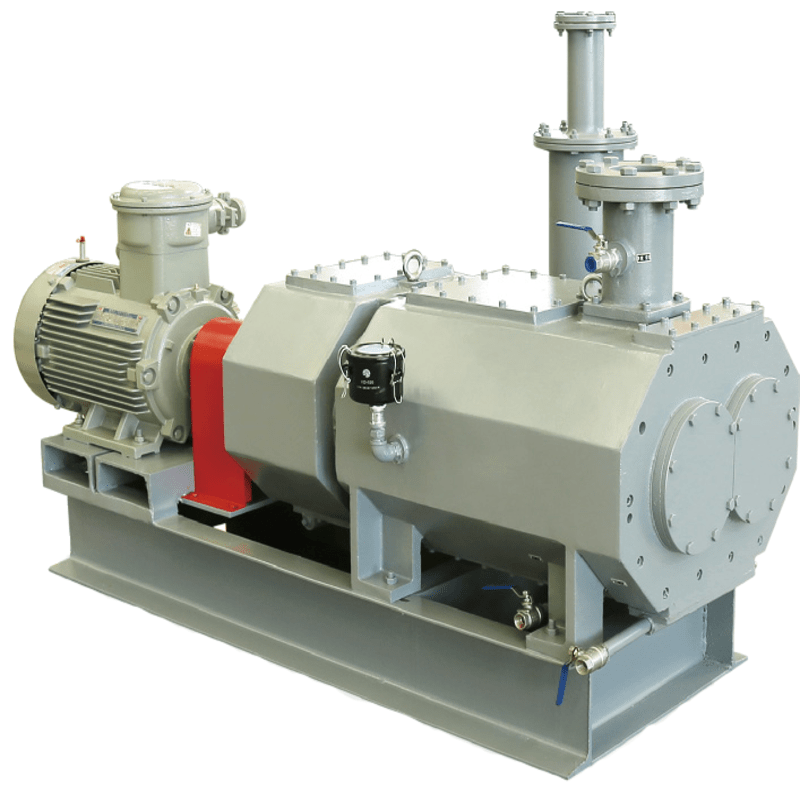

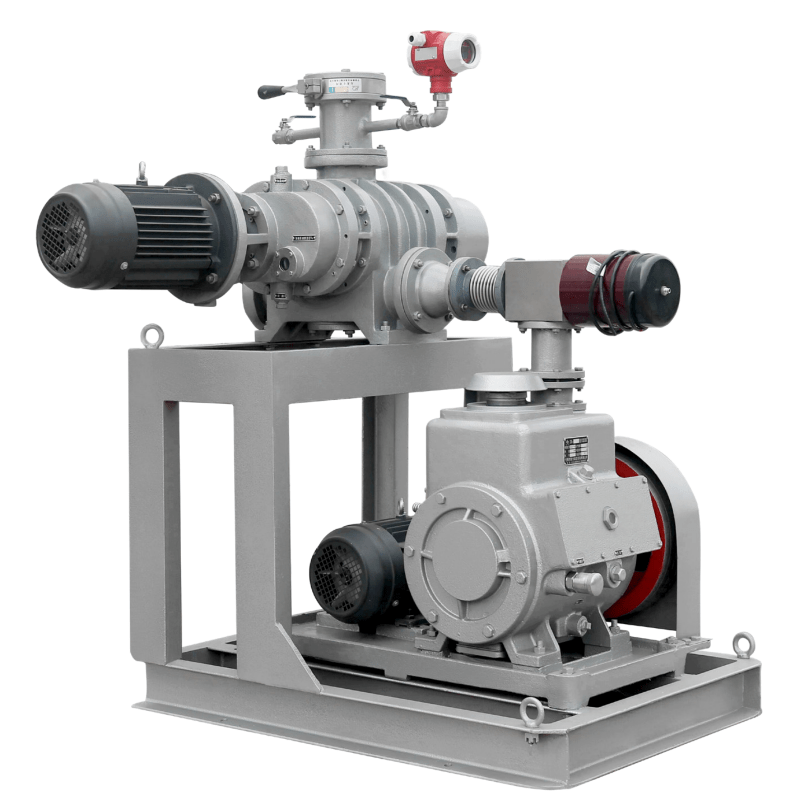

Principle description of JZJS Roots Vacuum Unit

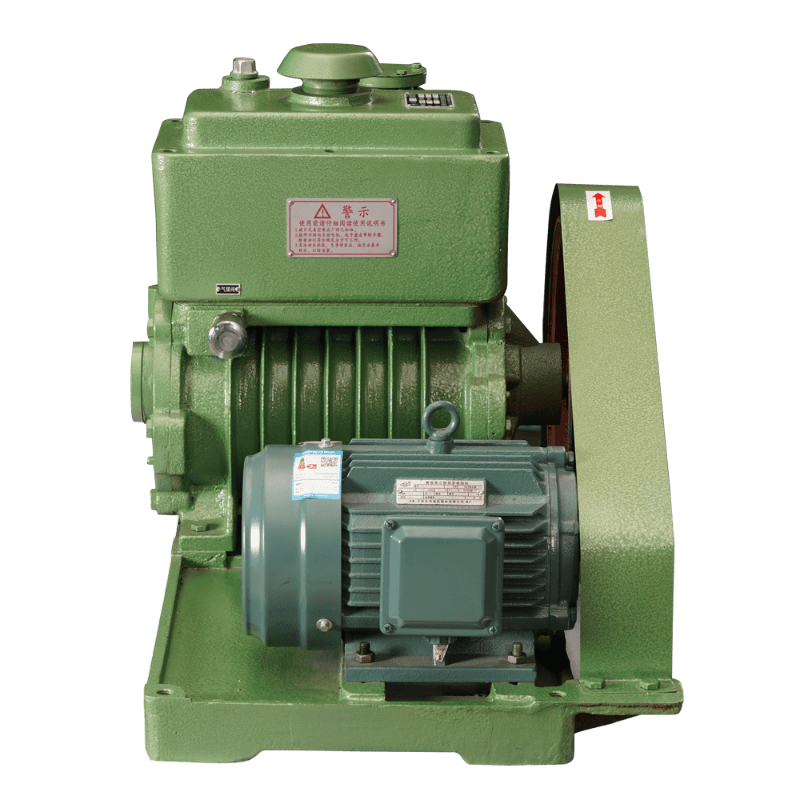

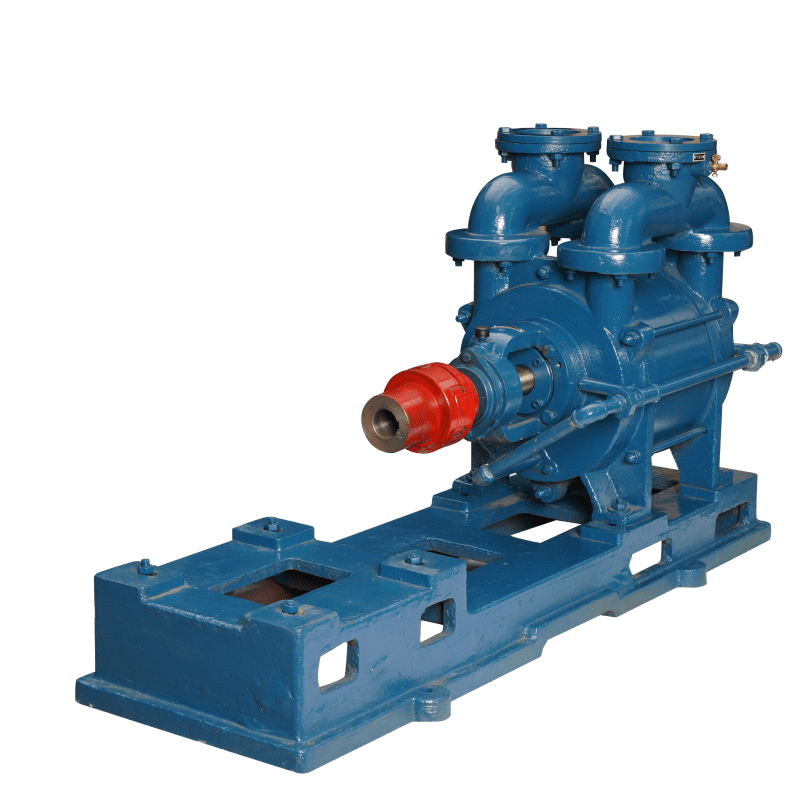

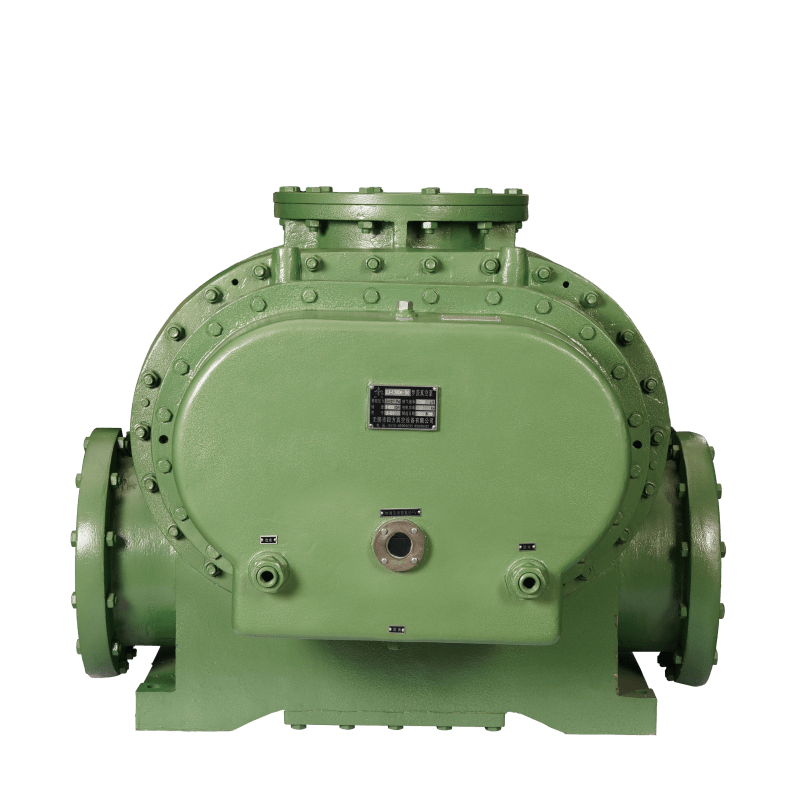

JZJS Roots water ring vacuum unit is composed of roots pump as main pump and water ring pump as backing pump in series. It is more advantageous for Roots water ring vacuum unit to select water ring pump as the backing pump than other vacuum pumps. It overcomes the limit pressure difference when using a single water ring pump (the limit pressure of the unit is much higher than that of the water ring pump), and has the disadvantage of low extraction rate under certain pressure, while retaining the advantage that Roots pump can work quickly and has a higher extraction rate. It is especially suitable for pumping large quantities of condensable steam, especially when the capacity of mechanical vacuum pump of gas-ballast oil seal to remove condensable steam is not enough, or the solvent used can deteriorate the performance of pump oil, or the vacuum system does not allow oil contamination. Flammable and explosive gases can also be removed when equipped with explosion-proof motors and electrical appliances and according to the corresponding safety rules. Therefore, Roots Pump-Water ring pump unit is widely used in vacuum distillation, vacuum evaporation, dehydration and crystallization in chemical industry. Freeze-drying in food industry; Vacuum drying in pharmaceutical industry; Polyester chip for light spinning industry; Vacuum system for altitude simulation test, etc.

Roots water ring vacuum unit is roughly divided into the following types:

(1) Roots Pump-Water ring pump: the role of water ring pump in the unit is to create the required pre-vacuum for Roots pump. Generally speaking, the limit vacuum of single-stage water ring pump is not high, but the pre-vacuum of Roots pump produced in China is high. Therefore, in practice, single-stage water ring pump is not used as the backing pump of Roots pump, while double-stage water ring pump with lower limit pressure is used as the backing pump, which can also reduce the limit pressure of the unit.

(2) The limit pressure of one Roots pump and one water ring pump is 400Pa, which can satisfy the general vacuum demand, but its application range is limited. If two Roots pumps are connected in series and combined with the water ring pump, the limit pressure of the unit can be greatly increased (up to 25Pa). Therefore, in this type, it is common to see two Roots pumps in series and then use two-stage pump as the backing pump (Figure 1) to form a unit. If a higher limit pressure is required, a combination of three Roots pumps and a water ring pump can be used with a limit pressure of up to 1 Pa.

(3) If the three-stage Roots water ring unit can not meet the limit pressure, Roots Pump-Water ring pump parallel mechanical vacuum pump can be used; This unit is mainly used in vacuum system which needs to deal with large amount of water vapor for a long time and has very high vacuum limit, such as in vacuum drying. In vacuum system requiring large amount of water vapor to be treated, it is appropriate to use water ring pump, but the limit vacuum of the whole unit is relatively low due to its low limit vacuum degree. Although in vacuum systems requiring high vacuum, mechanical vacuum pumps with high vacuum limit are required as backing pumps. Air-ballast mechanical vacuum pumps can be used in parallel with water ring pumps (Fig. 2) as front-end pumps for Roots pumps. When vacuum drying, pre-pump with water ring pump first, until water vapor is greatly reduced, then start the mechanical vacuum pump of air ballast and cut off the water ring pump. In situations where drying takes a long time, less cooling water and power is required, as shown in Figure 2.

Industry application

JZJS vacuum unit is especially suitable for the process of extracting large amount of water vapor and corrosive and condensable gases because it uses water ring pump as the backing pump. Such as: vacuum distillation, evaporation, dehydration, crystallization, drying and other processes.

|

Function Model |

Pumping speed(L/S) | Ultimate pressure (Pa) | Construction of pump unit | Motor Power (KW) | Connections of inlet(mm) | Connections of outlet(mm) | Weight(KG) | ||

| Main pump | Holding pump | Backing pump | |||||||

| JZJS30-1 | 30 | 400 | ZJ30 | 2SK-1.5 | 4.75 | Φ50 | Φ40 | 300 | |

| JZJS70-2 | 70 | 400 | ZJ70 | 2SK-1.5 | 5.5 | Φ80 | Φ40 | 325 | |

| JZJS70-1 | 70 | 400 | ZJ70 | 2SK-3 | 9 | Φ80 | Φ40 | 420 | |

| JZJS150-2 | 150 | 400 | ZJ150 | 2SK-3 | 10.5 | Φ100 | Φ40 | 525 | |

| JZJS150-2A | 150 | 400 | ZJ150 | SZ-250 | 14 | Φ100 | Φ100 | 610 | |

| JZJS150-1 | 150 | 400 | ZJ150 | 2SK-6 | 18 | Φ100 | Φ50 | 650 | |

| JZJS300-2 | 300 | 400 | ZJ300 | 2SK-6 | 19 | Φ150 | Φ50 | 985 | |

| JZJS300-2A | 300 | 400 | ZJ300 | SZ-360 | 19 | Φ150 | Φ100 | 1015 | |

| JZJS300-1 | 300 | 400 | ZJ300 | 2SK-12 | 26 | Φ150 | Φ100 | 1485 | |

| JZJS600-2 | 600 | 400 | ZJ600 | 2SK-12 | 29.5 | Φ150 | Φ100 | 1520 | |

| JZJS600-2A | 600 | 400 | ZJ600 | 2SK-20 | 44.5 | Φ150 | Φ125 | 2630 | |

| JZJS600-1 | 600 | 400 | ZJ600 | 2SK-30 | 62.5 | Φ150 | Φ125 | 3030 | |

| JZJS1200-2 | 1200 | 400 | ZJ1200 | 2SK-30 | 66 | Φ300 | Φ125 | 4070 | |

| JZJS30-11 | 30 | 25 | ZJ30 | ZJ30 | 2SK-1.5 | 5.5 | Φ50 | Φ40 | 380 |

| JZJS70-21 | 70 | 25 | ZJ70 | ZJ30 | 2SK-1.5 | 6.25 | Φ80 | Φ40 | 420 |

| JZJS70-12 | 70 | 25 | ZJ70 | ZJ70 | 2SK-1.5 | 7 | Φ80 | Φ40 | 440 |

| JZJS70-11 | 70 | 25 | ZJ70 | ZJ70 | 2SK-3 | 10.5 | Φ80 | Φ40 | 535 |

| JZJS150-21 | 150 | 25 | ZJ150 | ZJ70 | 2SK-3 | 12 | Φ100 | Φ40 | 600 |

| JZJS150-12 | 150 | 25 | ZJ150 | ZJ150 | 2SK-3 | 13.5 | Φ100 | Φ40 | 710 |

| JZJS150-11 | 150 | 25 | ZJ150 | ZJ150 | 2SK-6 | 21 | Φ100 | Φ50 | 920 |

| JZJS300-41 | 300 | 25 | ZJ300 | ZJ70 | 2SK-3 | 13 | Φ150 | Φ40 | 1000 |

| JZJS300-22 | 300 | 25 | ZJ300 | ZJ150 | 2SK-3 | 14.5 | Φ150 | Φ40 | 1150 |

| JZJS300-21 | 300 | 25 | ZJ300 | ZJ150 | 2SK-6 | 22 | Φ150 | Φ50 | 1350 |

| JZJS300-12 | 300 | 25 | ZJ300 | ZJ300 | 2SK-6 | 23 | Φ150 | Φ50 | 1510 |

| JZJS300-11 | 300 | 25 | ZJ300 | ZJ300 | 2SK-12 | 30 | Φ150 | Φ100 | 1880 |

| JZJS600-41 | 600 | 25 | ZJ600 | ZJ150 | 2SK-6 | 25.5 | Φ150 | Φ50 | 1365 |

| JZJS600-22 | 600 | 25 | ZJ600 | ZJ300 | 2SK-6 | 26.5 | Φ150 | Φ50 | 1665 |

| JZJS600-21 | 600 | 25 | ZJ600 | ZJ300 | 2SK-12 | 33.5 | Φ150 | Φ100 | 1980 |

| JZJS1200-41 | 1200 | 25 | ZJ1200 | ZJ300 | 2SK-12 | 37 | Φ300 | Φ100 | 3100 |

| JZJS1200-22 | 1200 | 25 | ZJ1200 | ZJ600 | 2SK-12 | 40.5 | Φ300 | Φ100 | 3200 |

| JZJS1200-22A | 1200 | 25 | ZJ1200 | ZJ600 | 2SK-20 | 55.5 | Φ300 | Φ125 | 4270 |

| JZJS1200-21 | 1200 | 25 | ZJ1200 | ZJ600 | 2SK-30 | 73.5 | Φ300 | Φ125 | 4670 |

Company Strength Introduction

Our company is one of the largest manufacturing enterprises of vacuum obtaining equipment in China. The company always adheres to the working attitude of "Professional & Precision" to constantly increase the technological content of products, as well as the developments and innovations of products. At present, there are vacuum pumps of rotary vane series (2X, XD), water ring series (SZ, 2SK, SK, 2BE), reciprocating series (WLW), roots series (ZJ) of nine specifications, roots-water ring units (JZJS), roots-rotary vane unit (JZJX), roots- reciprocating pump unit (JZJW), and other products, which are widely used in metallurgy, chemical industry, medicine, textile, food, aviation, electronic, scientific research and other industries and sections.

Our company has a strong technical force, and a professional team for the design and manufacture of vacuum obtaining equipment. In addition, we keep close cooperative relationships with domestic and foreign scientific research institutes, universities and colleges, and have advanced product technologies, good performances and perfect services. With decades of R&D and manufacturing experience in vacuum obtaining equipment, we have trained an experienced team in production and technical services to ensure that we provide our users with high-quality products and excellent services. We pursue the "Ease & Convenient" as our service tenet, and through the continues efforts of our all staff, Sifang Vacuum Equipment Co., Ltd. will create the greatest value and return for you.

Notes in choosing vacuum pump

- The limit pressure of vacuum pump shall meet this technology's working pressure. In general, the limit pressure shall one order of magnitude lower than technological requirements

- Each pump has a certain working pressure range. Thereafter, the working point of pump shall be within this range. It can not work for a long time beyond the allowable working pressure.

- Under the working pressure, the vacuum pump shall discharge all gas generated during technological process in the vacuum device.

- Choose the vacuum unit:

(1) When use one pump which can not satisfy the suction and vacuum demands, shall combine several pumps and they can complement each other and then can meet the technological requirements.

(2) Some vacuum pumps can not work under the atmospheric pressure, shall need forevacuum. Some vacuum pumps discharge pressure is lower than atmospheric pressure, shall need backing pump, thereafter, they are combined for use. The pumps which are combined are called vacuum pump unit which makes the vacuum system gets good vacuum degree and discharge amount. Because different vacuum pump needs different demands for discharged gas, e.g. in normal condition, Roots—sliding unit is not available for the gas contained much coagulate gas, we shall choose correctly the combined vacuum pump.

- When you choose the oil sealed pump, you shall first know that if your vacuum needs the demand for the oil pollution or not. If the device needs no oil strictly, you shall choose various no oil pumps, such as: water ring pump, low temperature pump. If the demand is not strict, can choose the oil pump and adds some oil pollution protection measures, e.g. adds cold trap, oil protection trap, baffle, etc which can reach cleaning vacuum demands.

- Know the discharged gas component. Inspect the gas if it contains the coagulate vapor, particle, dust or it is corrosive or not. When choose the vacuum pump, shall know the gas component and choose the proper pump according to the discharged gas. If the gas contained the vapor, particle and corrosive gas, shall consider installing the auxiliary equipment in the air inlet pipe of the pump such as: condenser, dust collector.

- When choose the oil sealed vacuum pump, shall consider the effect to the environment by the oil vapor discharged from vacuum pump. If the oil vapor shall not allow the pollution, shall choose the non oil vacuum pump or discharge the vapor out of the room.

- The vibration generated during the vacuum working affects the technological process and environment or not. If the technological process does not allow, shall choose the non vibration pump or take the vibration proof measures.

- The price, operation and maintenance cost of vacuum pump

Taking into account all above conditions, decide a proper solution for you.

(1) Lowest investment cost.

(2) Lowest production operation cost

(3) Feasible solution after considering above two conditions

The best working range for vacuum pump

Pump type |

oil sealed mechanical pump |

water steam jet ejector |

Roots pump |

oil booster pump |

oil diffusion pump |

Optimal working range (Pa) |

10²–10 |

10⁵–10² |

10²–1 |

1–10⁻¹ |

5×10⁻²–10⁻⁴ |

Laws and formulas

1. Fore pumping speed of Roots pump

S=(0.1~0.2)S{Roots}

2. Pumping speed selection of roughing vacuum pump

S=Q1/P{forepumping}

S=2.3Kq* V*lg(Pa/P{forepumping}/t

- Effective pumping speed of mechanical pump (L/s)

- Effective pumping speed of Roots pump (L/s)

- Leakage rate of vacuum system (Torr-L/s)

- Forevacuum degree needs to reach to (Torr)

- Volume of vacuum system (L)

- Time required for reaching to P{Forepumping}.

- Atmospheric pressure (Torr)

- Those related to pressure P under correction coefficients and equipment terminal values