- Overview

- Recommended Products

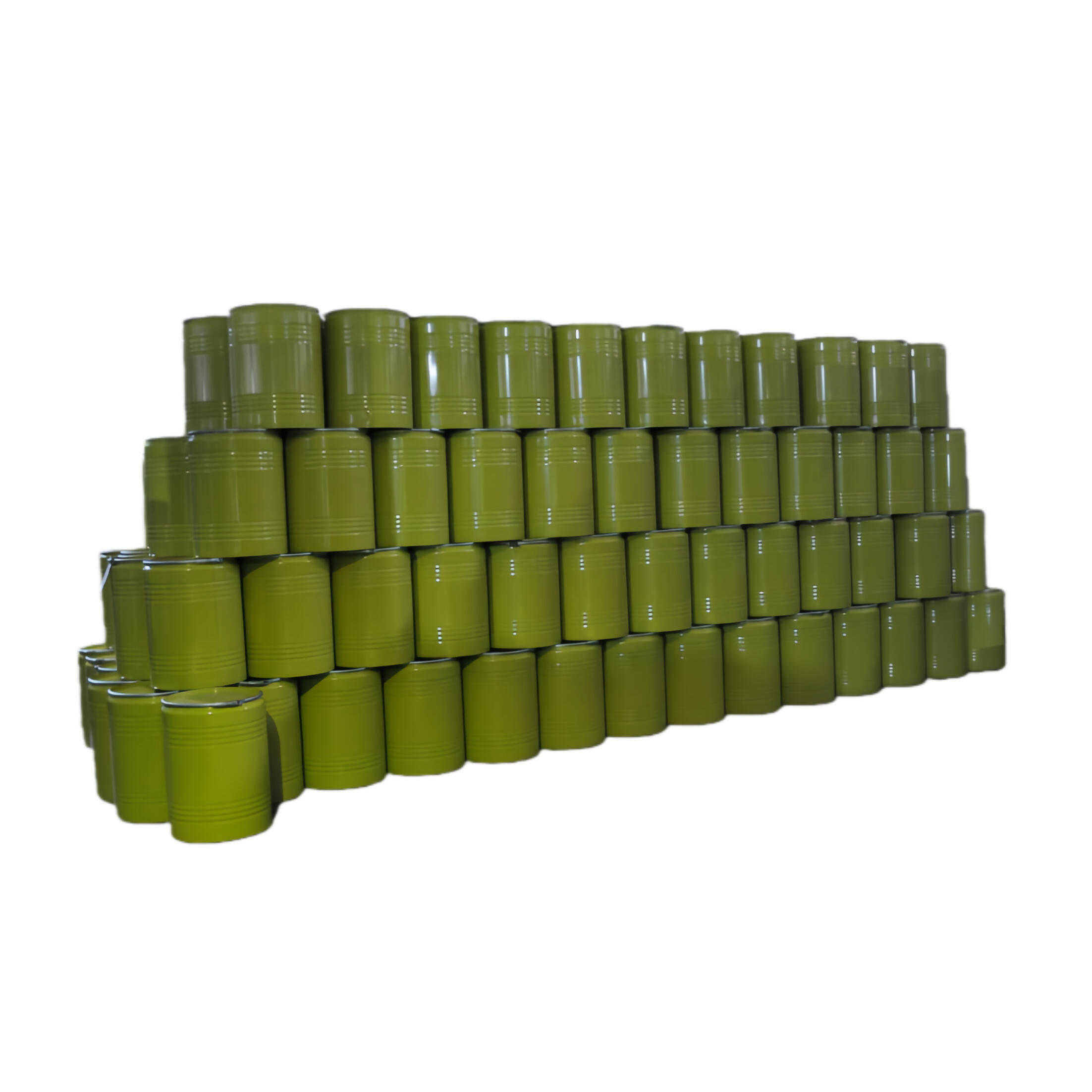

Product Overview

The Normal 1000L IBC, manufactured byWuxi Sifang Youxin Co., Ltd. , is a durable, cost-effective, and standardized packaging solution designed for the storage and transportation of liquid and semi-liquid materials.

Built with a high-strength inner plastic container encased in a galvanized or stainless steel cage frame, it offers a combination of chemical resistance, mechanical strength, and reusability. Its design complies with international standards, making it suitable for chemical, food, pharmaceutical, coating, and agricultural applications.

The 1000L IBC is the most widely used ton container globally, recognized for its excellent handling efficiency, stackability, and compatibility with automated filling and discharge systems.

Product Specifications

Product Name: Normal 1000L IBC (Intermediate Bulk Container)

Nominal Capacity: 1000 liters (optional 800L–1200L)

Inner Container Material: High-density polyethylene (HDPE), UV-resistant grade

Outer Frame Material: Galvanized or stainless steel cage

Pallet Base: Steel, plastic, or composite (four-way forklift entry)

Valve Type: 2” or 3” ball or butterfly valve (customizable)

Filling Opening: DN150–DN225 with screw or clamp lid

Operating Temperature: -20°C to +70°C

Specific Gravity Rating: 1.5 / 1.9 (depending on liquid density)

Stacking Load: 1.8–2.0 tons

Compliance: ISO 9001, UN/DOT, ADR, FDA

Key Product Advantages

1.Universal Application

Suitable for a wide range of industries — from industrial chemicals to food-grade materials — providing a standardized, reliable solution for global logistics.

2.Durable Construction

The inner HDPE container resists most acids, alkalis, and solvents, while the metal cage protects against impact and deformation.

3.High Space Efficiency

The cubic shape allows maximum utilization of container and warehouse space, improving logistics efficiency compared to round drums.

4.Ease of Handling and Transport

Equipped with a four-way forklift base, IBCs can be easily moved, stacked, or integrated into automated filling lines

5.Leak-proof and Safe

Advanced blow-molding technology ensures a seamless container body, minimizing leakage risks during transport.

6.Reusable and Environmentally Friendly

Designed for multiple reuse cycles; containers can be cleaned, refilled, or recycled, reducing packaging waste and cost.

7.Optional Materials and Features

Customizable in anti-static, UV-resistant, or food-grade versions to meet specific environmental and safety needs.

Product Composition and Structure

Inner Container:

Blow-molded HDPE bottle, seamless and chemical-resistant.

Transparent or opaque for easy material visibility and protection.

Outer Frame:

Galvanized steel cage with welded crossbars for rigidity and impact protection.

Stainless steel frame optional for corrosive environments or food-grade use.

Top Section:

Large filling opening with dustproof screw or clamp cap.

Optional venting valve for safe gas release during filling.

Bottom Section:

Discharge outlet with valve and dust cap, ensuring controlled drainage.

Integrated sloped base ensures complete liquid discharge.

Pallet Base:

Available in steel, plastic, or hybrid materials, compatible with forklifts and conveyors.

Designed for four-way entry and easy stacking.

Manufacturing and Quality Control

Advanced Blow-Molding Technology:

Produces seamless HDPE containers with consistent wall thickness and high strength.

Welding and Frame Assembly:

Automated welding ensures precise fit and cage uniformity.

Leak and Pressure Testing:

100% of units are tested for air and hydrostatic pressure before shipment.

Load and Impact Testing:

Drums undergo drop, stacking, and vibration tests per UN and ISO standards.

Material Traceability:

Every component is batch-tracked to ensure compliance and quality consistency.

Applications

The Normal 1000L IBC is designed for broad industrial and commercial use, covering a wide spectrum of liquids and semi-liquids.

Chemical Industry: Solvents, lubricants, detergents, adhesives, coatings.

Food and Beverage: Edible oils, syrups, dairy ingredients, flavorings.

Pharmaceuticals: Liquid formulations, cleaning solutions, intermediates.

Agriculture: Pesticides, fertilizers, and irrigation additives.

Water Treatment: Storage of purification chemicals and solutions.

Quality Assurance

Each IBC manufactured by Wuxi Sifang Youxin Co., Ltd. undergoes rigorous inspection before delivery to guarantee safe and consistent performance.

Leak Test: Every container tested under pressure for 30 minutes.

Stacking Test: Ensures long-term stability during warehouse storage.

Drop and Vibration Test: Simulates real-world transport conditions.

Visual Inspection: Verifies weld integrity and surface quality.

Certification: UN/DOT markings available for export and hazardous goods.

Frequently Asked Questions (FAQ)

Q1: What materials can the IBC hold?

It can safely store most non-corrosive and mild corrosive liquids, including acids, alkalis, oils, and food products.

Q2: Is it reusable?

Yes. The container can be cleaned, refitted with new valves or lids, and reused multiple times.

Q3: Can it be customized?

Yes. We offer variations in material, valve size, lid type, and pallet base to meet your needs.

Q4: How is the IBC cleaned?

It can be washed using high-pressure water or steam, and chemical cleaning agents depending on the stored material.

Q5: Does it comply with export standards?

Yes. It meets UN/DOT and ADR standards for international hazardous and non-hazardous liquid transport.

Conclusion

The Normal 1000L IBC from Wuxi Sifang Youxin Co., Ltd. offers a balanced combination of practicality, strength, and versatility.

With its durable inner HDPE tank, reinforced metal cage, and global compliance certification, it provides a safe and efficient solution for storing and transporting liquids across industries.

Whether used for industrial chemicals, food ingredients, or agricultural liquids, this IBC ensures cost efficiency, reliability, and environmental responsibility, making it a trusted choice for modern bulk packaging needs.