- Overview

- Recommended Products

Product Overview

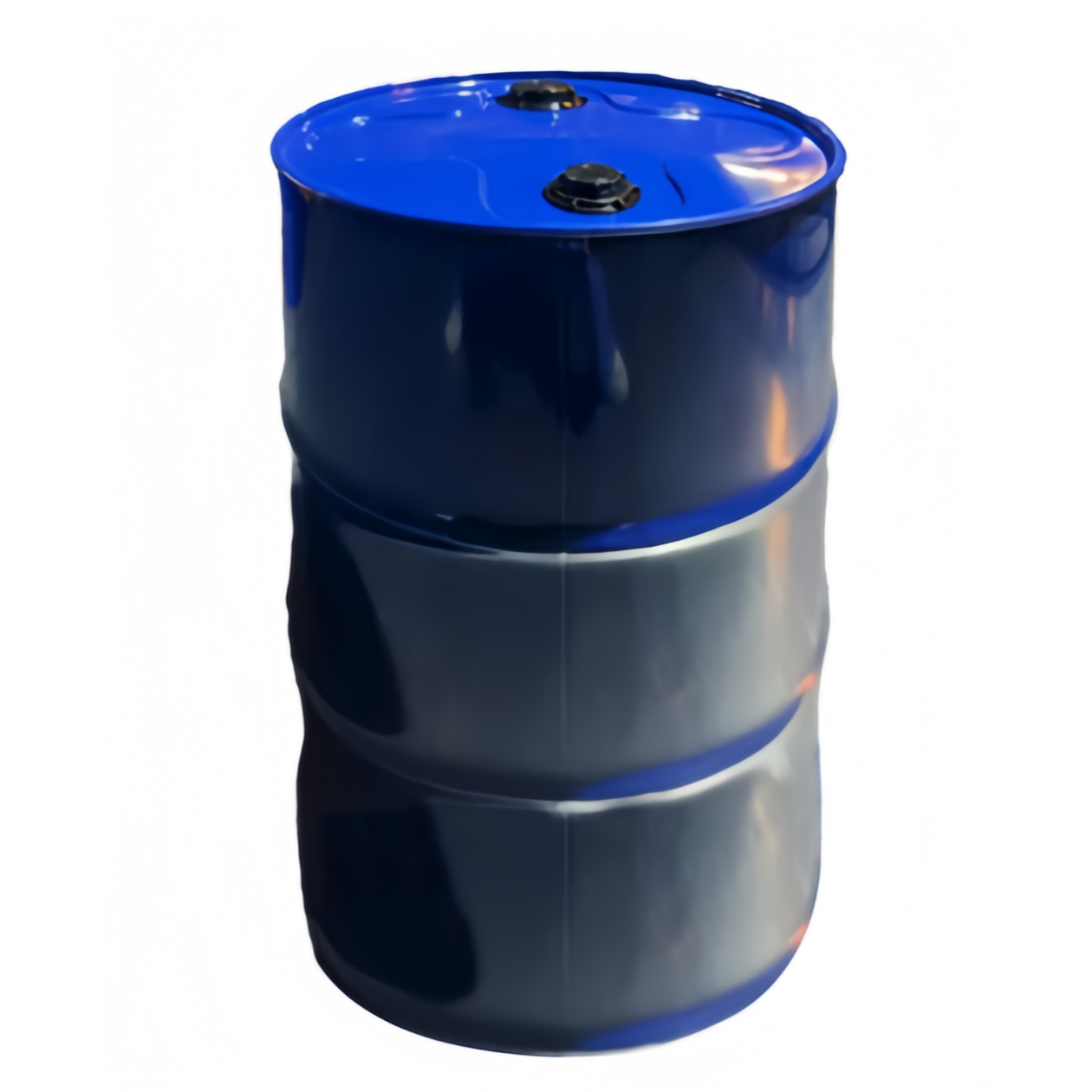

The Parallel Ring Type Composite Drums, manufactured by Wuxi Sifang Youxin Co., Ltd., represent an advanced form of industrial packaging that integrates the durability of a reinforced steel body with the flexibility and corrosion resistance of composite inner structures.

Characterized by parallel rolling rings along the body, these drums are designed for enhanced mechanical strength, stacking stability, and handling safety. The parallel ring reinforcement allows the drum to withstand internal pressure changes and external impacts, making it especially suitable for high-demand sectors such as chemical production, coatings, pharmaceuticals, and lubricants.

With options for open-head or closed-head configurations, these composite drums combine modern engineering design with environmentally responsible materials, providing a high-performance, long-life, and reusable packaging solution.

Product Specifications

Product Type: Parallel Ring Reinforced Composite Steel Drum

Drum Capacity: 50L – 230L (standard 200L, 205L, 210L, 230L)

Outer Material: Cold-rolled or hot-rolled carbon steel

Steel Thickness: 0.6 mm – 1.2 mm (customizable)

Reinforcement: Two to four parallel rolling rings (body reinforcement ribs)

Inner Surface Treatment:

Epoxy phenolic, pure phenolic, or PVF inner coating

Optional inner plastic liner (PE/PP composite)

Outer Coating: Solvent-based or water-based paint; customizable color and logo printing

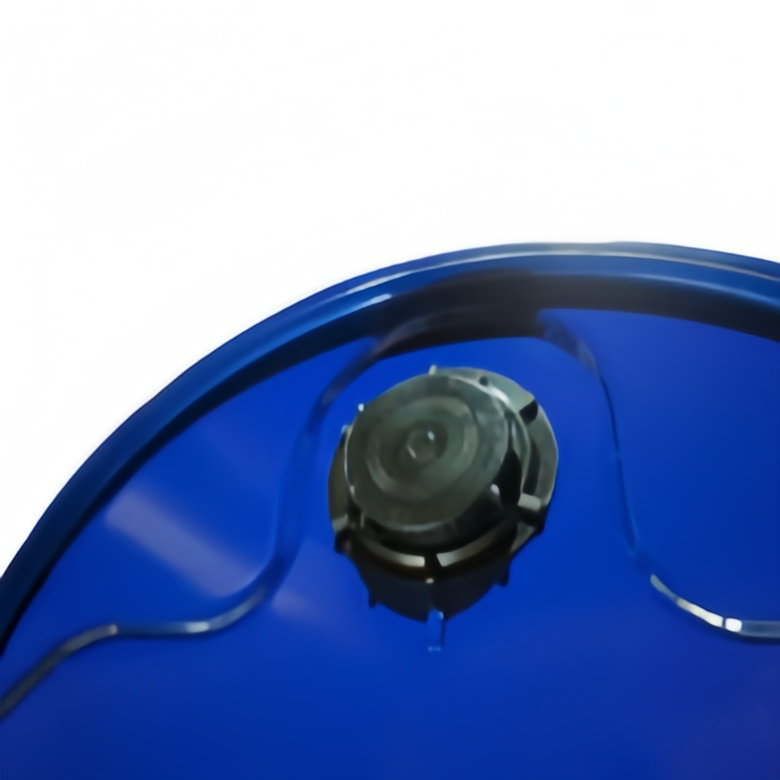

Lid Type:

Open-head: Removable lid with clamp or bolt ring

Closed-head: Integrated top with 2” and ¾” threaded openings

Sealing System: Metal or plastic gasket, UN-approved closure

Standard Compliance: ISO 9001, UN certification for hazardous goods, ROHS, FDA (optional)

Key Product Advantages

1.Enhanced Structural Strength

The parallel rolling rings on the drum body reinforce vertical rigidity, effectively preventing deformation during filling, stacking, or long-distance transportation.

2.Pressure and Impact Resistance

Reinforced rings distribute stress evenly across the barrel surface, improving resistance against internal expansion pressure or external mechanical impact.

3.Corrosion and Contamination Protection

The internal coating or composite liner isolates the contents from direct metal contact, providing excellent resistance to chemical corrosion and ensuring product purity.

4.Efficient Handling and Stackability

The parallel ring design enhances grip and facilitates mechanical handling, ensuring stable stacking during storage and container transport.

5.Versatile Application

Suitable for both liquid and solid materials, including flammable, corrosive, or high-value products, meeting the diverse needs of modern industrial users.

6.Environmental and Reusable Design

The drum’s structure supports easy cleaning and liner replacement, allowing for multiple reuse cycles and reducing overall environmental footprint.

Product Composition and Structure

1.Each Parallel Ring Type Composite Drum consists of a robust outer steel shell reinforced with parallel ribs and an internal protective layer that may be coated or lined, forming a composite structure with dual benefits:

Outer Steel Drum:

Made from high-quality carbon steel with precision-rolled seams and reinforced parallel rings.

Provides superior compression and impact strength.

Optionally coated with corrosion-resistant epoxy or water-based paints for outdoor durability.

Inner Composite Layer:

May include epoxy phenolic, PVF, or epoxy powder coating for anti-corrosion protection.

Optional plastic liner (PE/PP) for enhanced chemical resistance and cleanliness.

Ensures compatibility with acids, alkalis, solvents, lubricants, and food-grade products.

2.Manufacturing Process:

Steel Forming and Rolling: Creation of the drum body with precision-engineered parallel rings.

Welding and Assembly: Seam welding and flange forming to ensure leak-proof integrity.

Surface Treatment: Internal coating or liner insertion and external painting.

Inspection and Testing: Rigorous leak, pressure, and drop testing to ensure performance reliability.

Assembly and Handling

Open-Head Drums: Fitted with removable lids and sealed using bolt or clamp rings, ideal for solids and semi-liquids.

Closed-Head Drums: Fixed top with threaded openings for filling and discharge of liquids.

Sealing Options: Multiple closure systems including metal plugs, plastic bungs, and tamper-proof seals.

Stacking and Storage: Designed for secure vertical stacking with reinforced ring stability.

Handling: Compatible with forklifts, drum grippers, and conveyors for efficient industrial operations.

Applications

The Parallel Ring Type Composite Drums are engineered to serve a broad range of industries requiring durable, leak-proof, and corrosion-resistant packaging, including:

Chemical and Petrochemical Industry: For solvents, resins, adhesives, and chemical intermediates.

Paints and Coatings: Suitable for both water-based and solvent-based paints.

Lubricants and Oils: Ideal for motor oils, greases, and specialty lubricants.

Pharmaceuticals and Food Ingredients: Safe for high-purity and contamination-sensitive products.

Agricultural Chemicals: For storage and transport of pesticides, fertilizers, and additives.

Export Packaging: Certified for international transport of hazardous and non-hazardous materials.

Quality Assurance

Each drum produced by Wuxi Sifang Youxin Co., Ltd. undergoes strict multi-stage testing to ensure product reliability and consistency:

Leak Test: 100% inspection of sealing integrity.

Pressure Test: Simulated internal pressure to ensure burst resistance.

Corrosion Test: Salt spray and chemical immersion testing.

Drop Test: Impact testing to validate compliance with UN transport standards.

Coating Adhesion Test: Ensures uniform coverage and durability of internal and external coatings.

Frequently Asked Questions (FAQ)

Q1: What makes the parallel ring design superior to standard smooth drums?

The parallel rings provide greater structural strength and prevent deformation, making them ideal for heavy-duty or long-distance shipping.

Q2: Can the drum be reused or recycled?

Yes. The drum can be cleaned and reused, and the steel shell is fully recyclable after service life.

Q3: Are these drums suitable for food or pharmaceutical use?

Yes. With food-grade inner coatings or liners, they meet FDA and hygiene standards for sensitive materials.

Q4: What coating options are available?

Options include epoxy phenolic, pure phenolic, PVF (food-grade), and epoxy powder coatings.

Q5: Do you offer customization?

Yes. Drums can be customized by capacity, color, logo, coating type, or liner configuration.

Conclusion

The Parallel Ring Type Composite Drums from Wuxi Sifang Youxin Co., Ltd. combine strength, safety, and adaptability in one robust packaging solution.

Their reinforced parallel ring design ensures superior performance under pressure, while composite inner protection safeguards contents from corrosion and contamination.

Engineered for both industrial durability and environmental responsibility, these drums stand as a reliable choice for global manufacturers seeking high-quality, reusable, and regulatory-compliant packaging solutions.

From chemicals to food-grade products, Sifang’s parallel ring composite drums deliver proven safety and unmatched efficiency across every industry application.