- Overview

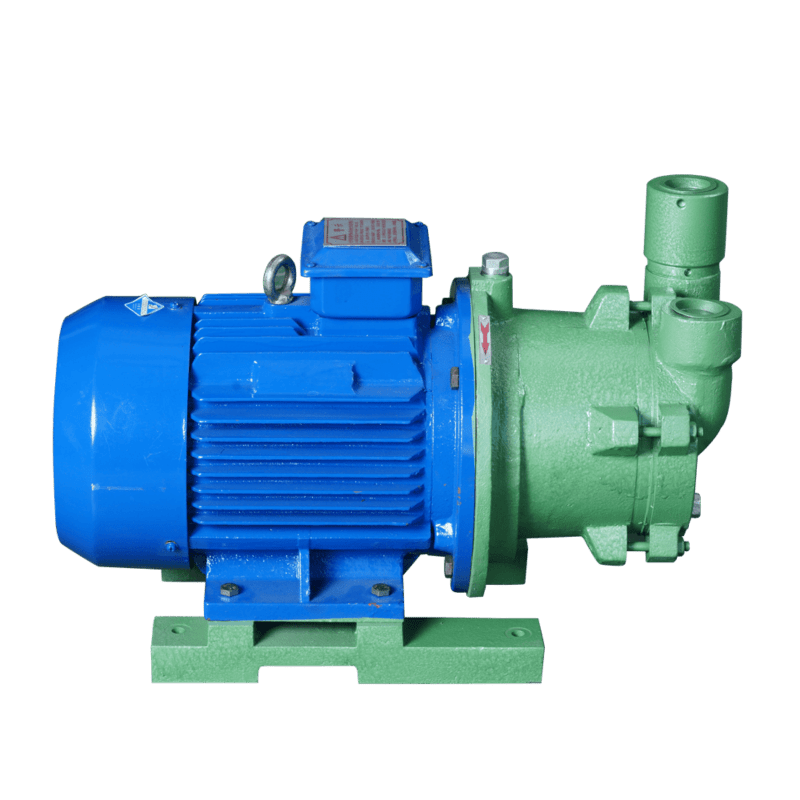

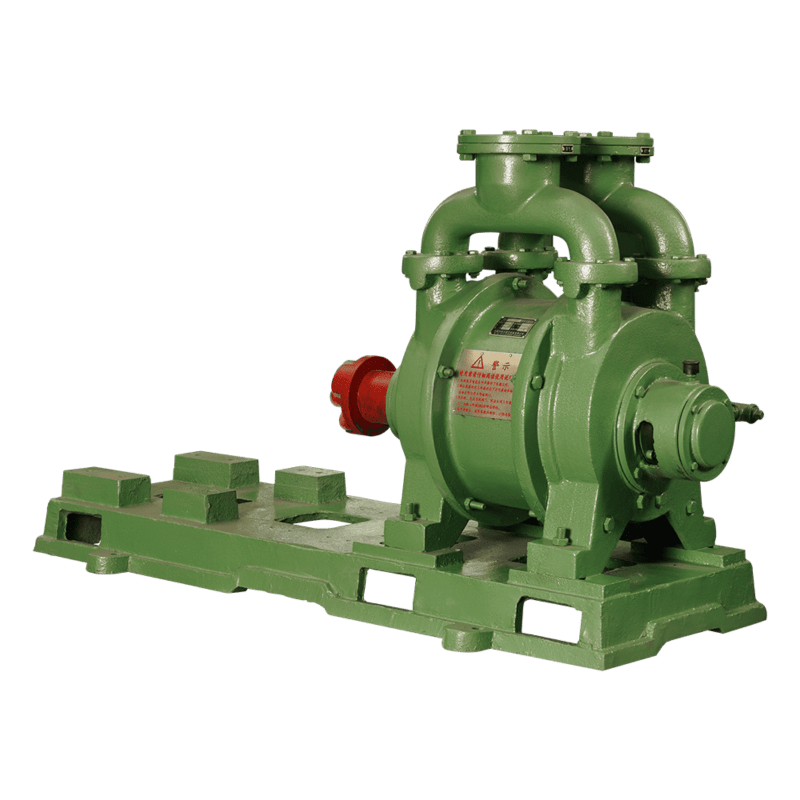

- Recommended Products

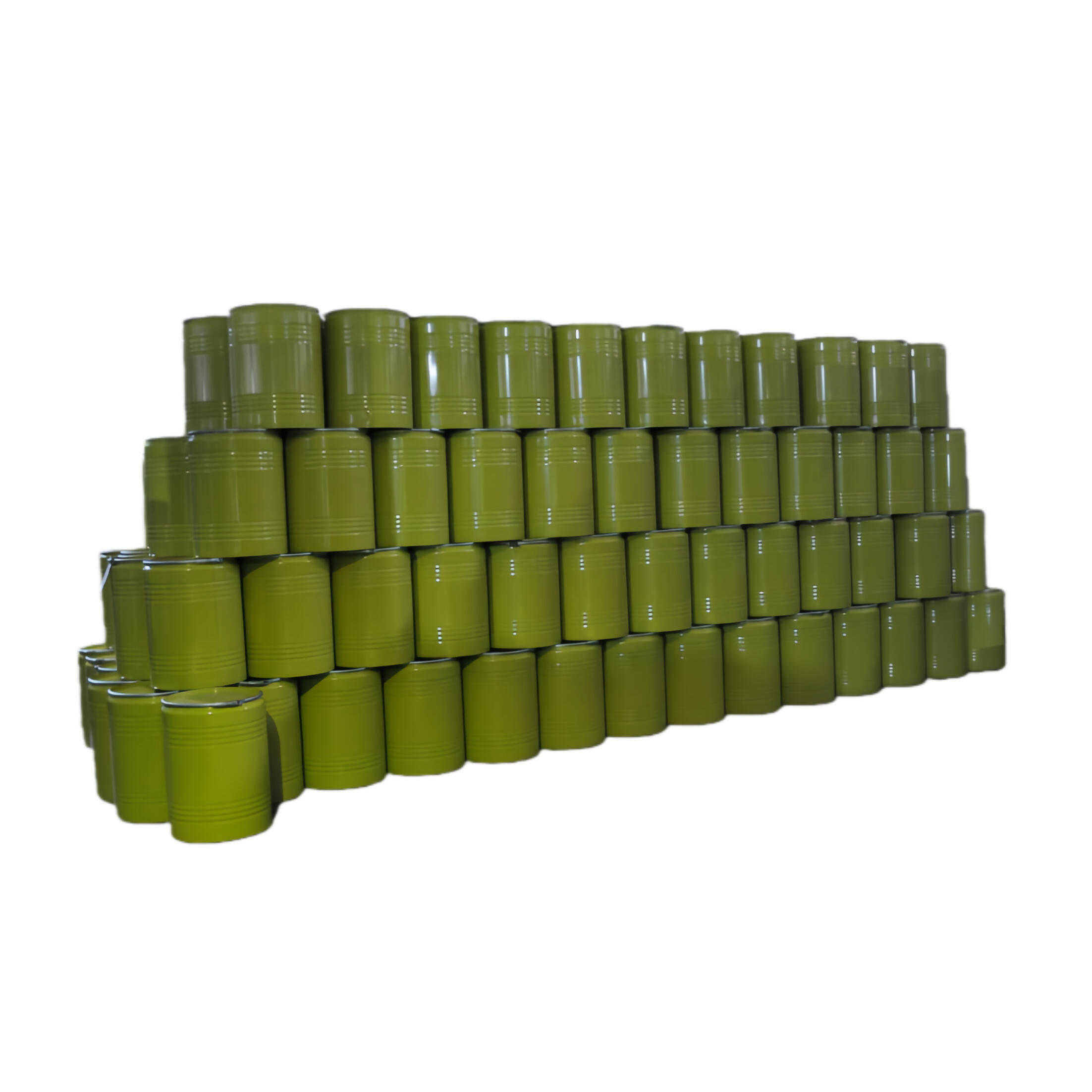

Product Overview

The Explosion-proof 1000L IBC, developed by Wuxi Sifang Youxin Co., Ltd., is a high-safety bulk packaging container specifically designed for the storage and transportation of flammable, explosive, or electrostatically sensitive liquids.

This container is built with anti-static and conductive materials, combined with reinforced metal grounding systems to prevent static discharge during filling, handling, or transport. It maintains all the convenience and capacity benefits of the standard IBC, while adding enhanced explosion-proof performance, static dissipation capability, and compliance with hazardous goods transport standards.

The Explosion-proof IBC is widely used in petrochemical, coatings, solvents, and fine chemical industries, where safety and environmental compliance are essential.

Product Specifications

Product Name: Explosion-proof 1000L IBC (Anti-static Intermediate Bulk Container)

Nominal Capacity: 1000 liters

Inner Container Material: Conductive HDPE with anti-static additives (surface resistance ≤10⁶ Ω)

Outer Frame Material: Galvanized or stainless steel with grounding points

Grounding System: Built-in electrostatic discharge (ESD) connection terminal

Pallet Base: Steel or conductive composite, four-way forklift entry

Valve Type: 2” or 3” conductive ball or butterfly valve

Filling Opening: DN150–DN225 with conductive cap and vent option

Operating Temperature: -20°C to +70°C

Explosion Protection Grade: Suitable for Zone 1 and Zone 2 hazardous areas

Compliance: ATEX / IECEx / UN / DOT / ISO 9001

Key Product Advantages

1.Explosion-proof and Anti-static Design

The container’s inner layer and components are made from anti-static modified HDPE, allowing safe dissipation of static electricity to prevent spark generation during loading and unloading.

2.Enhanced Safety Grounding System

Equipped with a metallic grounding network integrated into the frame, ensuring a continuous conductive path from the liquid to the ground. This greatly reduces ignition risks in volatile environments.

3.Chemical and Mechanical Resistance

The explosion-proof materials maintain the same chemical resistance and impact strength as standard HDPE, ensuring long-term performance under harsh industrial conditions.

4.Versatile Compatibility

Suitable for flammable solvents, alcohols, paints, coatings, adhesives, fuels, and other Class 3 or Class 4 dangerous goods.

5.Compliance with International Safety Standards

Fully tested and certified under ATEX and IECEx directives, guaranteeing safe use in hazardous zones such as chemical plants and coating workshops.

6.Reusable and Sustainable

Designed for repeated use with easy cleaning and reconditioning options, helping to reduce cost and environmental impact while maintaining high safety standards.

Product Composition and Structure

Inner Container:

Made of conductive high-density polyethylene (HDPE) blended with carbon-based anti-static agents.

Smooth, seamless design prevents chemical residue and contamination.

Outer Frame:

Galvanized or stainless steel cage with integrated grounding connectors.

Rigid structure protects inner bottle from external impact and deformation.

Top Section:

Conductive screw or clamp lid with optional pressure venting device.

Designed to prevent static accumulation during filling or vapor release.

Bottom Section:

Conductive outlet valve and dust cap ensuring controlled discharge without static buildup.

Sloped inner base for complete drainage.

Grounding System:

Built-in metal grounding terminal for external grounding wire connection.

Ensures reliable electrical continuity between inner container, valve, and frame.

Manufacturing and Quality Control

Specialized Conductive Blow Molding:

Advanced production process ensuring uniform distribution of conductive additives and consistent electrical performance.

Static Resistance Testing:

Each container undergoes surface resistance and grounding continuity tests.

Leakproof and Pressure Testing:

Containers are pressure-tested to prevent leakage under filling and stacking conditions.

Explosion-proof Verification:

Compliance with EN 60079 and ATEX 2014/34/EU safety standards verified by accredited laboratories.

Durability and Impact Tests:

Drop and vibration tests simulate real-world transport in hazardous environments.

Applications

The Explosion-proof 1000L IBC is ideal for industries where static electricity poses potential ignition hazards.

Petrochemical Industry: Storage and transport of solvents, fuels, and lubricants.

Coatings and Paints: Safe packaging for flammable coatings, thinners, and resins.

Fine Chemicals: Handling of organic solvents and intermediate compounds.

Pharmaceuticals: Transportation of alcohol-based disinfectants and reagents.

Energy Sector: Temporary storage of battery electrolytes, oils, and additives.

Quality and Safety Assurance

Every explosion-proof IBC from Wuxi Sifang Youxin Co., Ltd. is rigorously inspected and tested to guarantee safe operation in hazardous environments.

Static Resistance Verification: Each unit must meet ≤10⁶ Ω resistance requirement.

Grounding Continuity Check: Ensures uninterrupted conductivity between all metal components.

UN/DOT Certification: Suitable for the transport of dangerous goods under global standards.

Visual and Structural Inspection: Confirms the integrity of welds, valves, and seals.

Traceability: Each IBC marked with serial number and certification record for tracking.

Frequently Asked Questions (FAQ)

Q1: What makes this IBC explosion-proof?

The use of conductive materials and a complete grounding system prevents static buildup, minimizing ignition risk in volatile environments.

Q2: Can it be used for regular non-hazardous materials?

Yes, it can safely store standard liquids as well, though it is primarily designed for flammable or static-sensitive materials.

Q3: Does it require special maintenance?

Regular inspection of grounding connections and valve conductivity is recommended for continued safety compliance.

Q4: Is it compatible with existing IBC handling systems?

Yes. The structure and dimensions conform to ISO standards and can be used on the same pallets, conveyors, and filling lines as regular IBCs.

Q5: How long is the service life?

With proper cleaning and grounding maintenance, the IBC can be reused multiple times over several years.

Conclusion

The Explosion-proof 1000L IBC represents the perfect balance between capacity, safety, and durability for industries handling flammable or hazardous liquids.

With its anti-static design, robust structure, and international safety certifications, it ensures maximum protection for personnel, facilities, and transported goods.

As a product of Wuxi Sifang Youxin Co., Ltd., this explosion-proof IBC combines engineering precision, safety innovation, and global compliance, offering a reliable packaging solution for high-risk applications where safety cannot be compromised.