Product description:

ZGQ Single-chamber Vacuum High Pressure Gas Quenching Furnace is mainly used for bright quenching of tool steel, die steel, with small deformation and no need for secondary cleaning. The heating chamber adopts graphite tube heating, and the thermal-protective coating adopts a composite thermal insulation structure of graphite soft felt and graphite hard felt. For products with high color requirements or special materials, the metal screen structure of molybdenum and stainless steel composite insulation can also be adopted according to the special requirements of customers; The size of valid zone can be customized according to customer requirements; Equipped with low-temperature convection heating system;

| ZGQ Single-chamber Vacuum High Pressure Gas Quenching Furnace |

| Model |

Valid zone |

Maximum temperature (℃) |

Heating power (kw) |

Ultimate vacuum (Pa) |

Gas cooling pressure (bar) |

| ZGQ-40 |

450x300x300 |

1320 |

40 |

5x10-3or4x10-1 |

10 |

| ZGQ-80 |

600x400x400 |

1320 |

80 |

5x10-3or4x10-1 |

10 |

| ZGQ-120 |

700x500x500 |

1320 |

120 |

5x10-3or4x10-1 |

10 |

| ZGQ-150 |

900x600x600 |

1320 |

150 |

5x10-3or4x10-1 |

10 |

| ZGQ-300 |

1500x800x800 |

1320 |

300 |

5x10-3or4x10-1 |

10 |

Advantages and functions of vacuum heat treatment

Heat treatment is an important basic process to improve the performance, reliability and service life of mechanical parts. Heat treatment can maximize the excavation and play the potential of metal materials, so that mechanical parts can fully meet the performance requirements and service life under various service conditions. The advantages of vacuum heat treatment are no oxidation, no decarbonization, no pollution; clean surface, small distortion; excellent comprehensive mechanical properties; wide application; high automation; high production efficiency, stable product quality and energy saving. Vacuum heat treatment can be widely used in annealing, annealing, oil (gas) quenching, high pressure (high flow rate) gas quenching, vacuum carburization, vacuum sintering, vacuum brazing and other fields.

The process characteristics of vacuum heat treatment are vacuum degassing, vacuum degreasing effect, vacuum purification effect and vacuum protection effect.

Degassing of vacuum: steel parts in the vacuum heating process reduce the furnace pressure, that is, increase the vacuum degree, the residual gas (H, N, CO, etc.) in the steel will escape (degassing), thereby improving the mechanical properties of steel parts, mold parts after vacuum quenching, plasticity, impact toughness will be improved, thereby prolonging the service life.

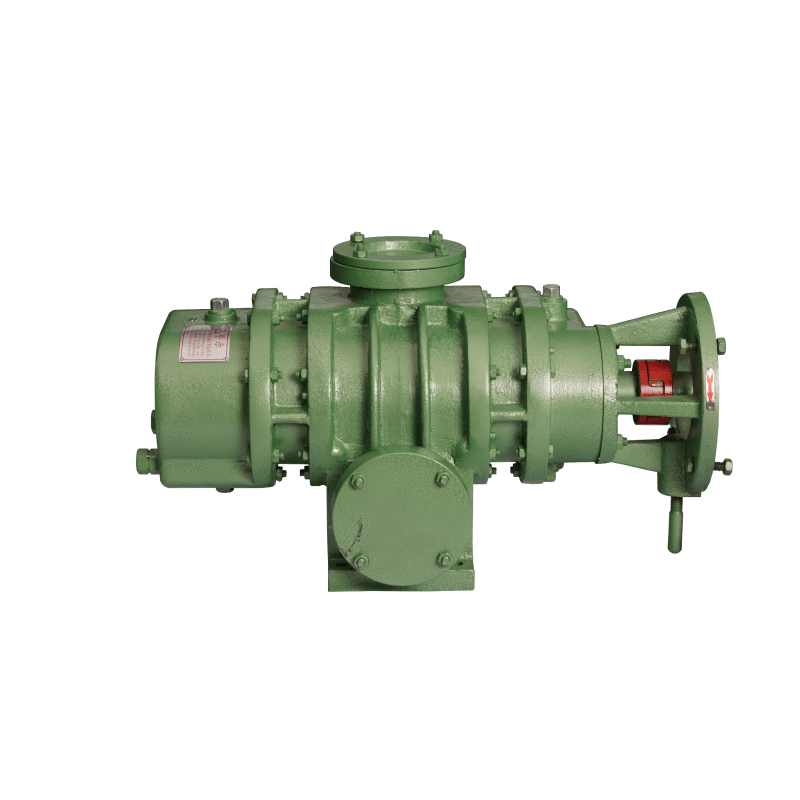

Vacuum degreasing effect: vacuum degreasing furnace has been widely used in metal foil, wire drawing and precision degreasing treatment of metal parts with small hole mesh. Because the grease attached to these objects belongs to the ordinary aliphatic group, which is a compound of carbon, hydrogen and oxygen, its vapor pressure is high, and when heated in a vacuum, it will quickly decompose into gases such as water vapor, hydrogen and carbon dioxide, and they are easily evaporated and pumped out by the vacuum pump. However, before vacuum heat treatment, the workpiece should still be cleaned and loaded into the furnace. Avoid a large amount of grease to contaminate the furnace and contaminate the vacuum pump to avoid damaging the performance of the vacuum pump.

Vacuum purification: the metal surface has oxide film, slight rust, nitrides, hydride, etc., when heated in vacuum, these compounds are reduced, decomposed or volatilized and disappear, so that the workpiece obtains a smooth surface.

Vacuum protection: when almost all metals are heated in an oxidizing atmosphere, the metal surface will oxidize and lose the luster of the metal, and vacuum heating can make the metal material maintain the original surface brightness.

Technical support & after-sales service

We not only provide customers with excellent performance equipment, but also provide perfect after-sales service.

At the same time, we make the following commitments to our customers:

When the equipment leaves the factory, provide corresponding spare parts and spare parts;

During the warranty period, any part damaged within the warranty scope will be repaired or replaced free of charge;

During the quality assurance period, if the equipment failure is outside the scope of the warranty, pay for repair or replacement shall be provided;

After the warranty period is exceeded, we provide paid but preferential after-sales service and spare parts supply;

Undertake the overhaul and spare parts supply of vacuum furnace and related equipment, and provide customers with professional maintenance services and reliable quality and reasonable price spare parts;

When you put forward an after-sales service request, we will reply within 2 hours, and if necessary, we can arrive at customer’s factory within 12 hours;

Provide a faster way according to the actual situation of users.

The selection of the vacuum furnace mainly involves the structure of the furnace, the size of the effective heating area, the pumping speed of the vacuum pump and the selection of the material of the heating room. Through the vacuum range of the product, the temperature treatment of the material and other factors, so as to choose the most appropriate product equipment.

1.Selection of effective heating zone

Vacuum furnace furnace size can be according to the heat treatment single product size, shape and a furnace capacity. Vacuum furnace is divided into horizontal (single chamber, double chamber, multiple chamber structure) and vertical vacuum furnace (slender parts suspension or plate parts heat treatment), limited by the structure and cost of horizontal single chamber structure is the most commonly used vacuum heat treatment furnace, vertical vacuum furnace due to the layout has lifting transmission system, procurement cost slightly higher, our commonly used horizontal vacuum furnace effective area size is as follows:

Furnace size |

Recommended effective working area (mm) |

Experimental type, small vacuum furnace |

300x200x200 450x300x300 |

Medium vacuum furnace |

600x400x400 700 x 500 x 500 900 x 600 x 600 1200 x 600 x 600 |

Large vacuum furnace |

1200 x 800 x 800 1500 x 800 x 800 2100 x 800 x 800 4000 x 1200 x 1200 |

Giant vacuum furnace |

6000 x 1300 x 1300 9000 x 1550 x 1830 |

The working vacuum should be selected according to the material and heating temperature. First, the working vacuum required for no oxidation heating should be met, and then the surface brightness, degassing and evaporation of alloy elements should be comprehensively considered. The working vacuum of commonly used materials is recommended as follows:

Vacuum heat treatment |

Recommended working vacuum |

Vacuum brazing |

Recommended working vacuum |

Steel (alloy tool steel, structural steel, bearing steel) |

1–10⁻¹Pa |

Aluminum products |

10⁻³Pa |

Alloy steel containing Cr, Ni, Si, etc |

10Pa |

Copper base products |

10⁻¹–10⁻²Pa |

Stainless steel, high-temperature alloy, iron, nickel, cobalt base |

10⁻²–10⁻³Pa |

Nickel-based products |

10⁻²–10⁻³Pa |

Titanium alloy |

10⁻³Pa |

Multicomponent alloy product |

10⁻¹–10⁻³Pa |

Copper alloy |

133–13.3Pa |

High speed steel Tempering |

1.3–10⁻² |

3. Selection of furnace shell material

Vacuum furnace shell is the working space from the sealed container, is also the basis of the furnace parts installation, furnace shell for double wall water cooling compression container, should have enough mechanical strength and stability, prevent force and heat after deformation and damage. According to the shell material is divided into all carbon steel material, and inner wall stainless steel material but other for carbon steel material.

4. Selection of heating and thermal insulation material

The equipment can choose different heating elements and heat insulation layers according to different operating temperatures. The commonly used heating element materials are heat-resistant steel(Cr20Ni80), high-purity graphite, molybdenum and alloys, etc. The temperature range is as follows. In addition to the selection of the above materials, it is necessary to comprehensively consider the energy consumption and stability under long-term use.

Operation Temperature |

Heating Element Selection |

Insulation Layer Selection |

≤800℃ |

High temperature nickel-chromium alloy |

Stainless steel |

800℃–950℃ |

High temperature nickel-chromium alloy (Cr20Ni80) |

Heat resistant steel + stainless steel |

950℃–1100℃ |

Molybdenum metal or heat resistant steel |

Heat resistant steel + graphite felt |

|

|

Molybdenum metal + stainless steel |

|

|

Molybdenum metal + graphite felt |

1100℃–1300℃ |

Molybdenum-lanthanum alloy |

Molybdenum-lanthanum alloy+ stainless steel |

|

High purity graphite |

Graphite soft felt + Graphite hard felt |

1300℃–1600℃ |

Molybdenum-lanthanum alloy |

Molybdenum-lanthanum alloy + stainless steel |

|

Isostatic pressed graphite |

Graphite soft felt + Graphite hard felt |

|

Tungsten alloy |

Tungsten alloy + Molybdenum-lanthanum alloy +stainless steel |

1600℃–2100℃ |

Isostatic pressed graphite |

Graphite soft felt + Graphite hard felt |

|

Tantalum |

Tantalum+Molybdenum-lanthanum alloy+Stainless steel |